Precision is Power: The newest CNC Press Brakes and Fiber Laser Cutting machines are essential investments for US manufacturers aiming for tighter tolerances and higher production speeds than ever before.

Tech Trends to Watch: Get ahead of the curve! Modern industrial machinery is now integrating advanced technology like AI for predictive maintenance and real-time monitoring to virtually eliminate costly downtime.

Local Support Matters: Choosing a domestic supplier is key. We detail why US-based support, fast part delivery, and local market understanding are crucial for profitability, making the right partnership essential.

The Smart Investment: This guide cuts through the confusion, offering a direct path to selecting high-ticket industrial equipment that will increase your capacity, reduce waste, and grow your bottom line.

The world of American manufacturing is always moving fast. If you’re a manufacturer, whether you’re running a massive operation in Michigan or a specialized fabrication shop in Seattle, you know that having the right machine is not just helpful, it’s the whole ballgame. You can’t afford guesswork, especially when you’re looking at serious, high-ticket capital equipment. You need industrial tools that are powerful, precise, and reliable enough to win those big contracts.

This is exactly why you are here. You’re not looking for a hobby machine; you’re looking for an industrial powerhouse. You want to buy the best equipment to make your business more profitable and efficient. We get it.

We will walk you through the top industrial CNC and metal fabrication technologies currently available, highlighting the features that are truly driving innovation for manufacturers like you across the United States.

Let’s look at the modern machines that are transforming how we cut, punch, and bend metal today.

When it comes to cutting metal, the old ways are fading fast. If you’re still relying on older CO2 or plasma technology for all your thin-to-medium sheet metal jobs, you are losing money every minute. The new standard is Fiber Laser Cutting, and the sheer speed and energy efficiency are game-changers for US manufacturers.

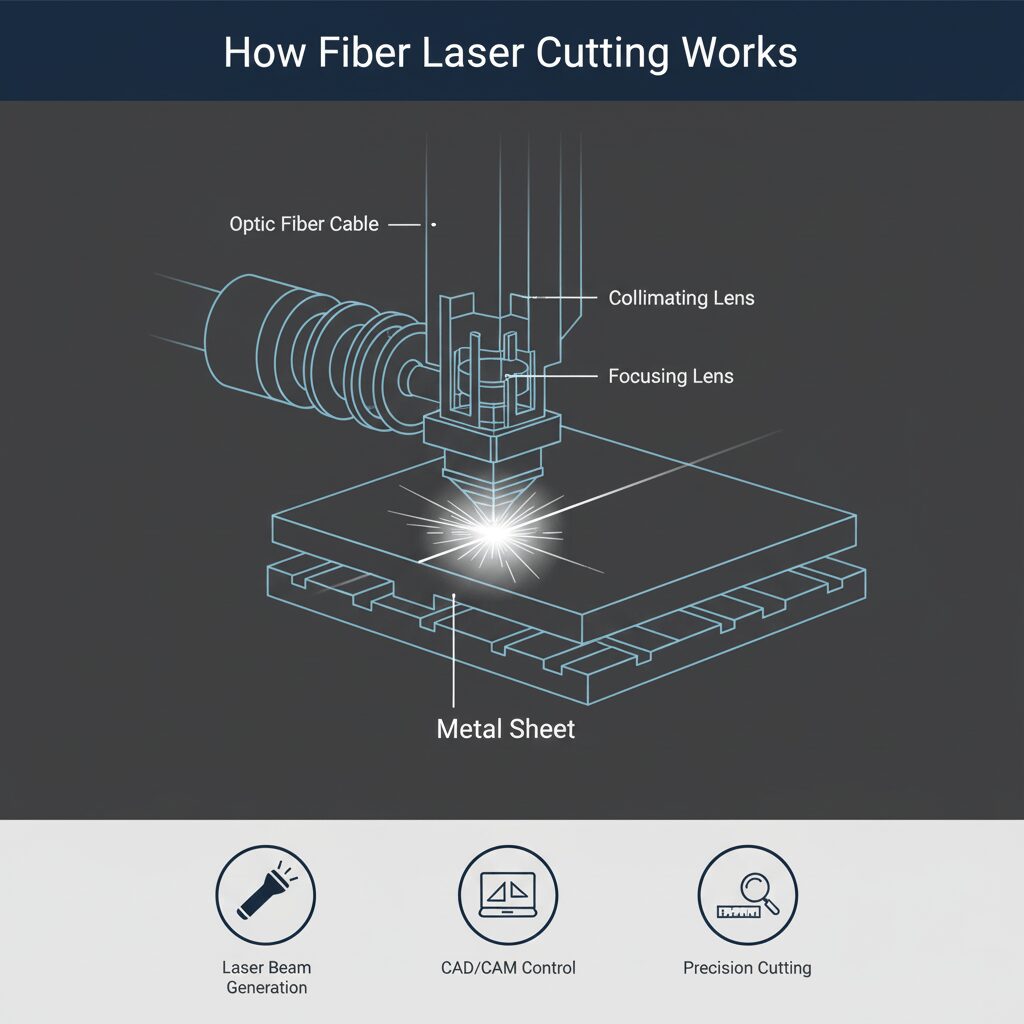

It’s surprisingly simple yet incredibly advanced. You create your part design using CAD/CAM software. This file generates machine code (G-Code). The powerful laser beam, created inside a fiber optic cable, is focused to a microscopic point. The CNC system then directs this high-power beam across the metal sheet, melting and vaporizing the material with micro-millimeter precision. The system automatically controls power, assist gas, and speed to give you a perfect, clean edge every time.

Bending and forming metal is an art, but in modern manufacturing, it needs to be a science. Your press brake is the backbone of metal forming. Today’s CNC Press Brake machines are miles ahead of older models, delivering unmatched control and repeatability that can mean the difference between a high-value contract and a pile of scrap.

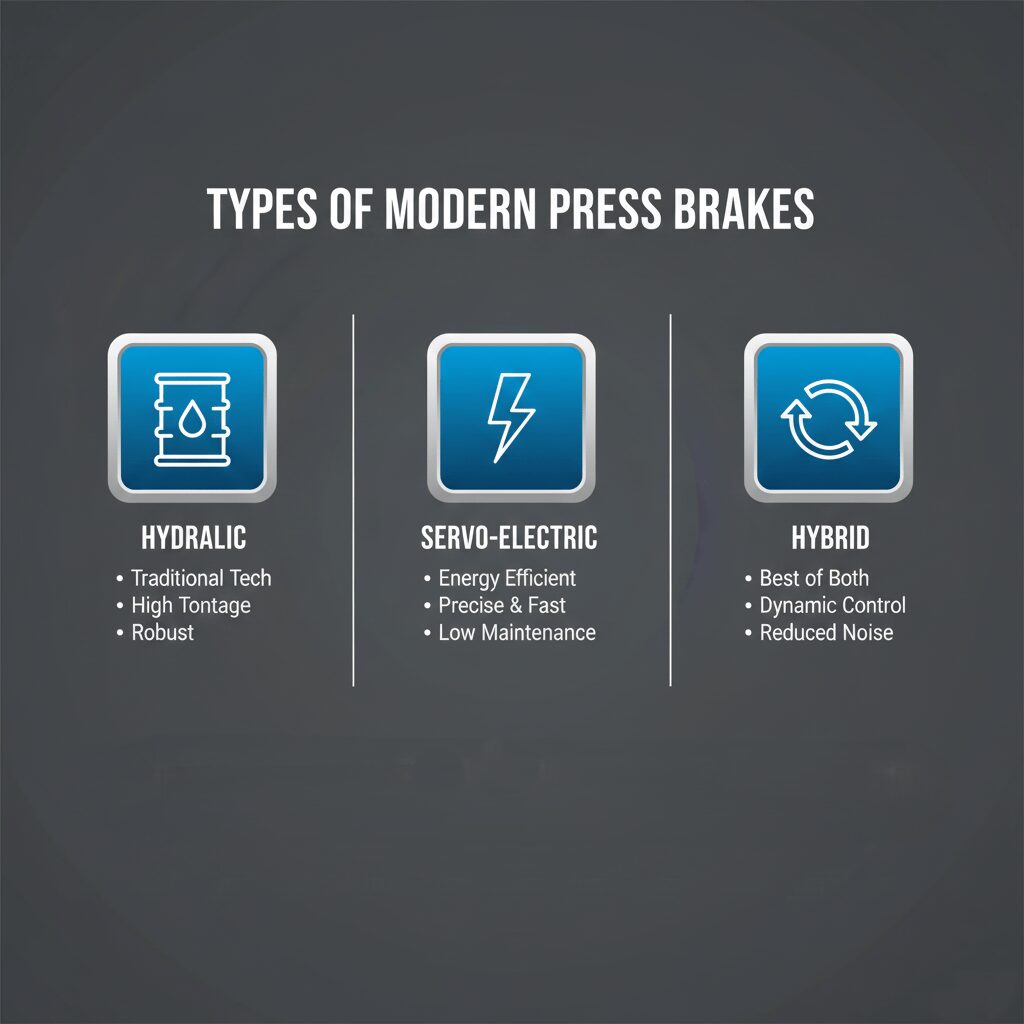

Type | Power Source | Primary Advantage | Best For |

Hydraulic | Oil Pressure | High Tonnage, Durability | Thick/Heavy Metal, Long Bends |

Servo-Electric | Electric Motor/Belts | Speed, Energy Efficiency, Silence | High-Volume, Repeatable Parts |

Hybrid | Electric & Hydraulic | The Best of Both Worlds: Speed with High Tonnage Capabilities | Versatile Job Shops, Complex Bends |

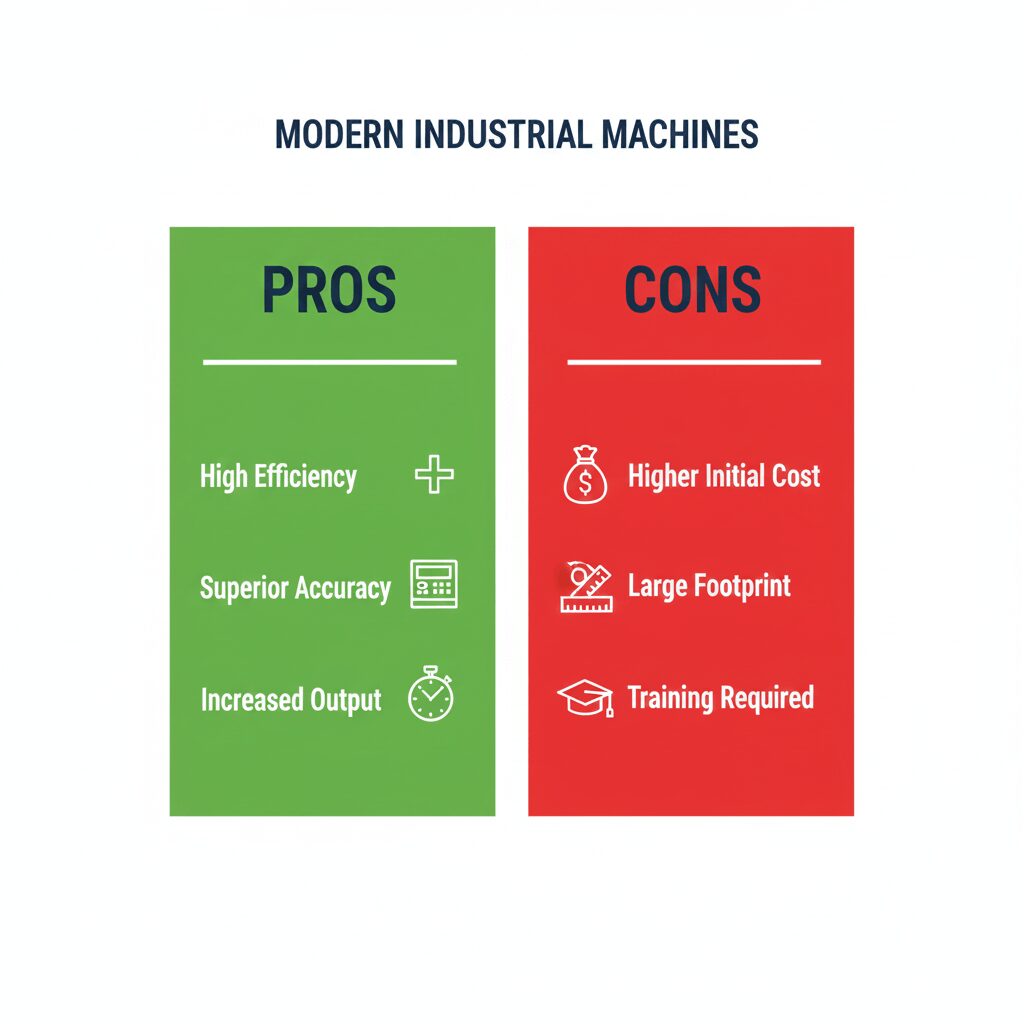

Pros | Cons |

Extreme Accuracy: Multi-axis backgauges (5 to 8 axes) allow for complex, perfect bends in a single setup. | High Upfront Cost: These are high-ticket items, an investment requiring significant capital. |

Reduced Waste: Precise control eliminates costly over-bending or under-bending errors. | Requires Skilled Operators: While controls are intuitive, programming complex parts still demands expertise. |

Faster Setups: Automated tool clamping and intuitive CNC controls slash the time spent between jobs. | Footprint: Industrial machines, especially high-tonnage models, require substantial factory space. |

To stay competitive in the US market, you need a machine that can deliver consistent quality, whether you’re in North Carolina or Oregon. The precision in a modern CNC Press Brake will help you secure contracts in demanding industries like aerospace and medical devices.

For simple shapes, notches, and high-volume hole-making, nothing beats a powerful CNC Punching Machine. These are true production workhorses, designed for raw speed and efficiency when the job doesn’t require complex laser cutting.

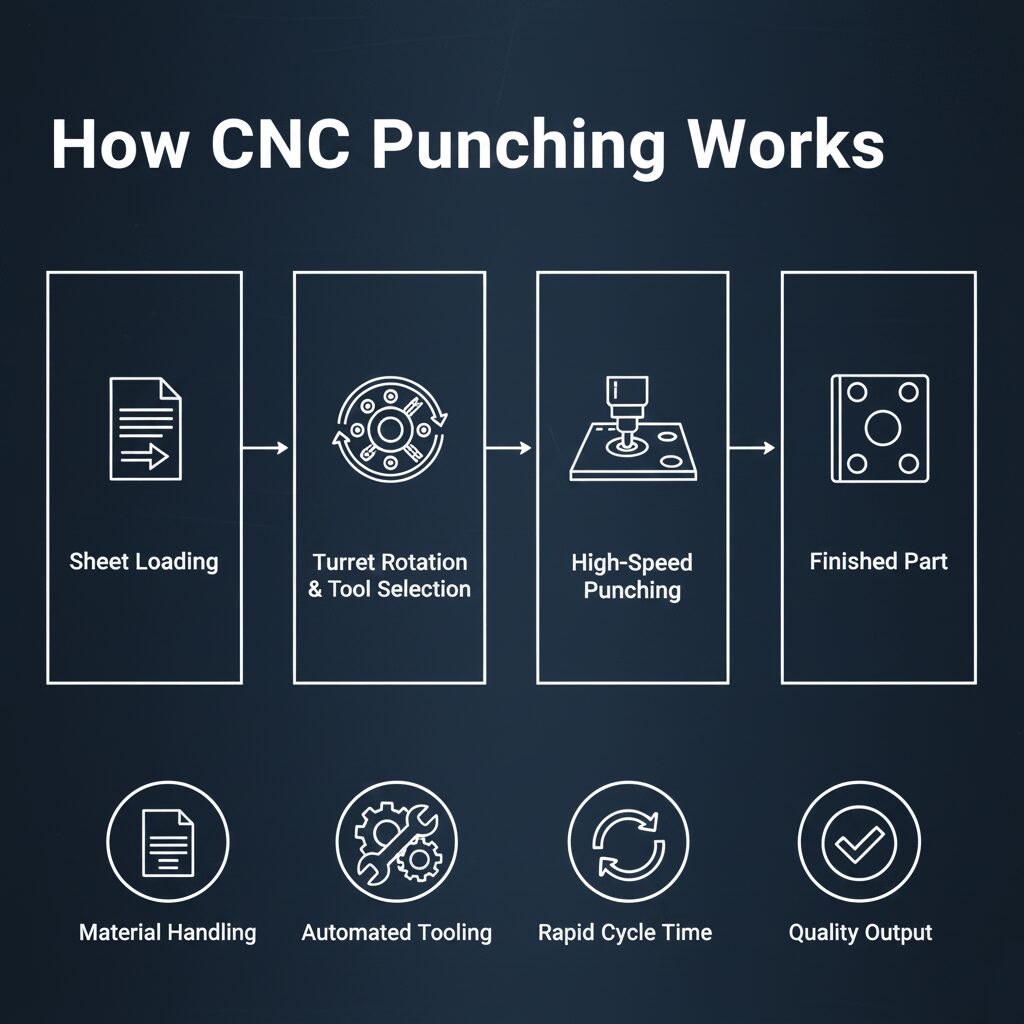

The machine uses a large turret (a circular disk) that holds many different tools (punches and dies). The CNC system quickly moves the metal sheet under the turret while the machine rapidly selects the correct tool and punches the hole or shape. This can happen hundreds of times per minute. The latest models integrate smart nesting software that optimizes the layout of parts on the sheet metal to maximize material usage and minimize waste, a smart way to save money!

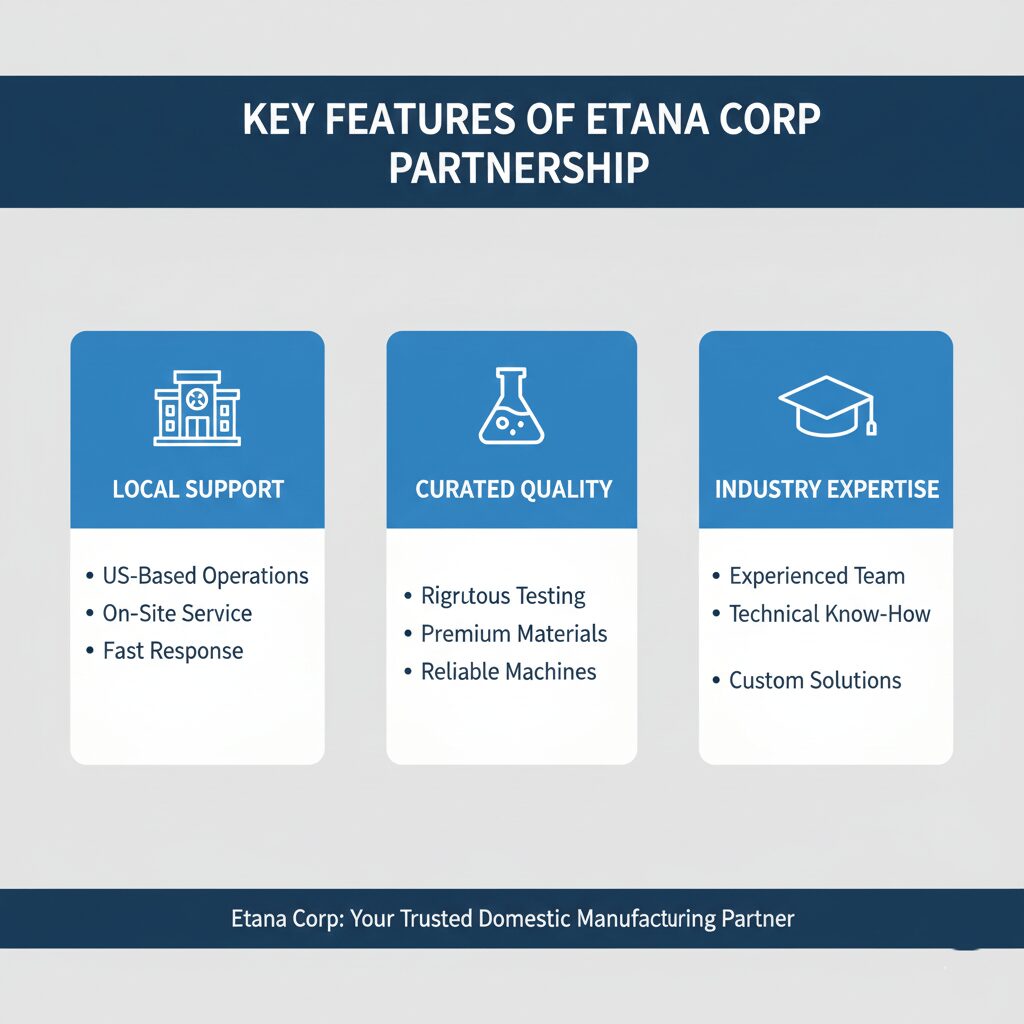

You have countless choices when buying a new piece of high-value machinery. But here’s the most important truth: the machine itself is only half the investment; the company that stands behind it is the other half.

For manufacturers across the country, from Miami, Florida, to Boise, Idaho, dependable support is non-negotiable. Downtime is a killer. Every hour your machine is stopped costs you thousands in lost production. This is where a truly committed, domestic supplier makes all the difference.

We are not just sellers of equipment; we are committed partners to the American manufacturing industry. We are proud to say that Etana Corp is one of the best fabrication and CNC machine suppliers in the United States, and our focus is on providing high-performance industrial machines backed by US-based support.

We understand the local market, the need for quick parts, and the urgency of getting you back up and running. If you are specifically looking at expanding your capabilities, you’ll want to review our extensive inventory and support for Fabrication Machines in Texas and beyond.

We focus purely on supplying the highest-quality machines. As such, we do not provide installation or training services. We recommend all our customers partner with qualified, local third-party providers for these specialized services to ensure safe and optimal machine setup.

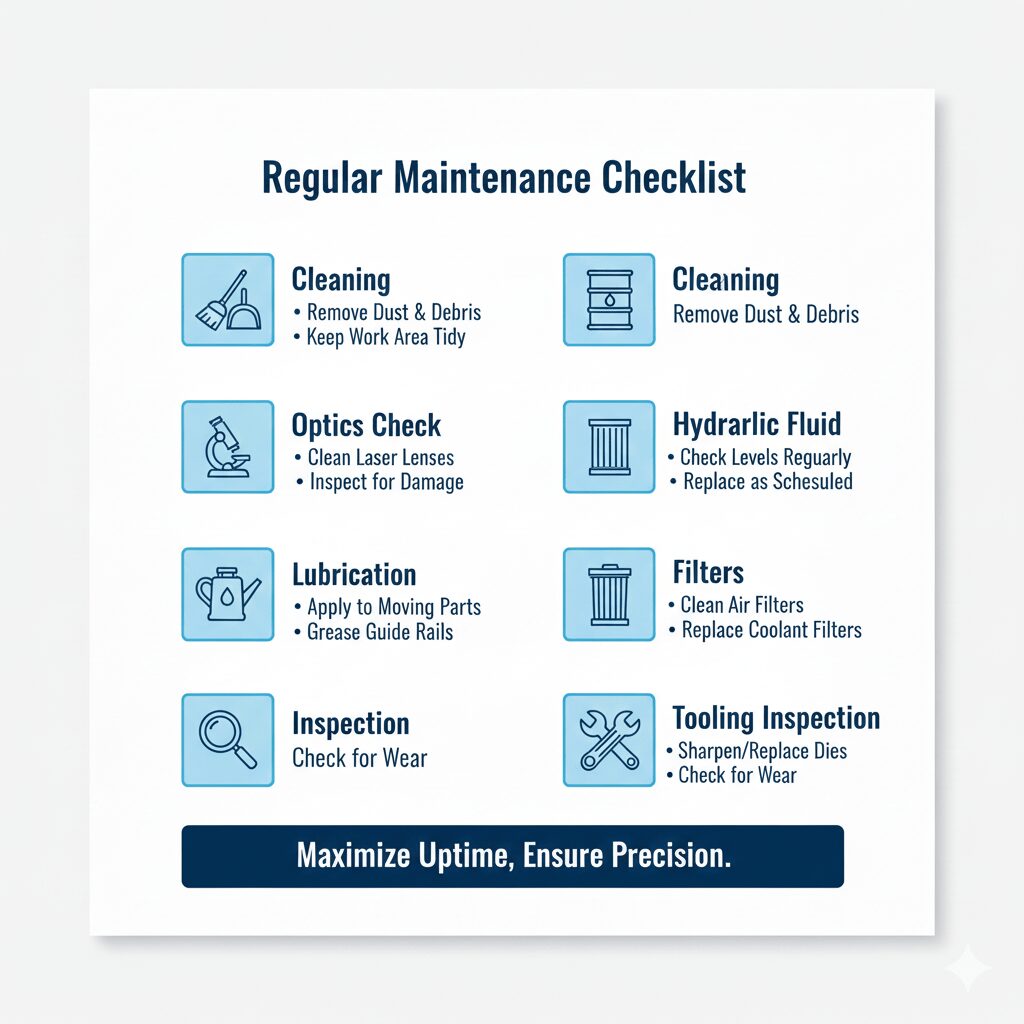

Keeping your high-ticket machinery running perfectly is critical. Proactive maintenance prevents costly breakdowns. Here are the simple but essential practices for your industrial CNC and fabrication machines:

Choosing to upgrade or purchase a high-end fabrication machine from a trusted source is not an expense; it’s an investment in your company’s future.

We believe in making the complex simple. The decision to invest in a major machine comes down to a clear understanding of its value proposition against the investment.

Feature | Fiber Laser Cutter | CNC Press Brake | High-Speed CNC Punch |

Primary Output | Intricate 2D Shapes, High Precision | Complex 3D Forms, Angles, Channels | High Volume Holes, Slots, Simple Shapes |

Best-in-Class Metric | Cutting Speed (Meters/Minute) | Angle Accuracy and Repeatability | Cycles Per Minute (SPM – Strokes) |

2025 Tech Trend | AI-Optimized Cutting Paths | Multi-Axis Backgauges (8+) | Automated Tool Management/Nesting |

Typical High-Ticket Price | $$$$ | $$$ | $$ |

US Industry Focus | Precision Sheet Metal (Automotive, Tech) | Structural Fabrication (Construction, Heavy Eq.) | HVAC, Electrical Enclosures, Appliances |

The biggest trends in manufacturing for 2025 are all about making your industrial machines smarter. These advancements are not just for the massive plants in Ohio or New York; they are scalable and essential for any US manufacturer looking to gain a competitive edge.

AI and Predictive Maintenance: Advanced sensors monitor machine vibration, temperature, and power draw. Machine Learning algorithms analyze this real-time operational data to predict exactly when a component might fail, before it actually breaks. This means you can order a replacement part and schedule maintenance before an unexpected shutdown, virtually eliminating costly emergency downtime.

To ensure your machine is equipped with the latest fabrication machine in the United States, make sure you’re buying a model that includes these smart capabilities.

Choosing the right high-ticket industrial CNC or fabrication machine is the single most important decision for future-proofing your business. It impacts your capacity, your quality, and your ability to win profitable contracts.

Don’t settle for machines that were good enough yesterday. Demand the latest in Fiber Laser, multi-axis Press Brake, and high-speed Punching technology, backed by a trusted American partner. We are committed to supplying the best possible equipment that maximizes your productivity and efficiency.

Etana Corp is one of the best fabrication and CNC machine suppliers in the United States. We focus on getting you the reliable, high-precision equipment you need, with the local support you deserve.

Ready to boost your production and secure your largest contracts? Contact Etana Corp today to request a quote or schedule a consultation on the right machine for your shop!

A CNC router (Computer Numerical Control) is a machine that uses a spinning cutter (router bit) to cut and engrave materials based on a computer program. In the industrial setting, this is typically used for woodworking, plastics, and non-ferrous metals. While we focus on industrial metal fabrication like Laser Cutting and Press Brakes, the core CNC control principle is the same: use a program for precise, repeatable motion.

The main purpose of any CNC machine is to replace manual labor with automated, high-precision work. This ensures every part is an exact copy of the last, achieving better quality, higher speed, and massive savings in material waste compared to hand-operated tools.

Operating a modern industrial CNC machine is simpler than ever thanks to intuitive, touch-screen controllers. The basics of loading a program and running the machine can be learned quickly. However, mastering the programming (CAD/CAM and G-Code) and the art of metal forming requires time, practice, and continuous learning.

For a serious US manufacturer, the question isn’t if it’s worth it, but which type of CNC machine you need. High-ticket industrial CNC machines (like the advanced Press Brakes and Fiber Lasers we supply) are absolutely worth the investment, often showing a rapid Return on Investment (ROI) by increasing part quality and production speed, which allows you to take on higher-value jobs.

While hobby-grade CNC routers are popular for small, custom crafts, industrial CNC and fabrication machinery is the foundation for high-value B2B businesses, including: custom sheet metal fabrication shops, aerospace component manufacturing, precision tooling and die production, and specialized architectural metalwork.

The information provided in this article is for general guidance and informational purposes only. While we at Etana Corp strive for accuracy, current machine specifications, pricing, and technology trends are subject to change without notice. Any decision to purchase high-ticket industrial equipment should be made in consultation with a professional sales representative and detailed technical specifications.

Etana Corp is a supplier of high-quality machinery and does not provide machine installation, operator training, or setup services. We strongly recommend seeking specialized, certified third-party services for these needs.

WhatsApp us