If you’re a manufacturer in the United States, whether you’re operating out of a bustling facility in Houston, Texas, or a cutting-edge shop in Detroit, Michigan, you know one thing for sure: time is money. Choosing the right machinery for your production line is one of the most important decisions you’ll ever make. This isn’t just about buying a piece of heavy equipment; it’s about investing in a partnership that keeps your business running smoothly. You need equipment that’s dependable, precise, and backed by a team that truly understands the unique demands of American manufacturing.

In a competitive landscape, the difference between profit and loss often comes down to the quality and efficiency of your fabrication and CNC machines. That’s why your search for a supplier shouldn’t end with the lowest price tag. You need a trusted partner who provides exceptional value, high-quality machines, and expert consultation, from the moment you start looking to years down the line.

When US manufacturers look for precision and reliability, they consistently turn to Etana Corp. We are proud to be recognized as one of the very best fabrication and CNC machine suppliers in the United States. Our mission is simple: to equip American businesses with the high-performance equipment they need to lead globally. From the heart of the country in cities like Midland, Texas, to the industrial hubs across all states, our focus is on delivering machinery that’s engineered for peak performance.

We understand that buying a machine is a major investment. That’s why we source and supply top-tier equipment, like advanced laser cutting machines, durable press brakes, and precise punching machines, that help you cut down on waste and dramatically increase your production speed. When you partner with us, you are not just getting a machine; you are securing a reliable backbone for your operations. We offer the specialized expertise you need to select the perfect machine for your specific job.

Ready to upgrade your line? Don’t delay your next big project. Contact Etana Corp today to request a quote for the machinery that will transform your production.

High-performance metal fabrication equipment automates complex processes that used to require extensive manual labor. This is the simple magic behind modern manufacturing:

These automated systems reduce human error, speed up production cycles, and handle demanding material loads, which is crucial for meeting tight deadlines, particularly in high-volume industries. For a more detailed look at the tools themselves, check out our guide on Metal Fabrication Tools and Equipment United States

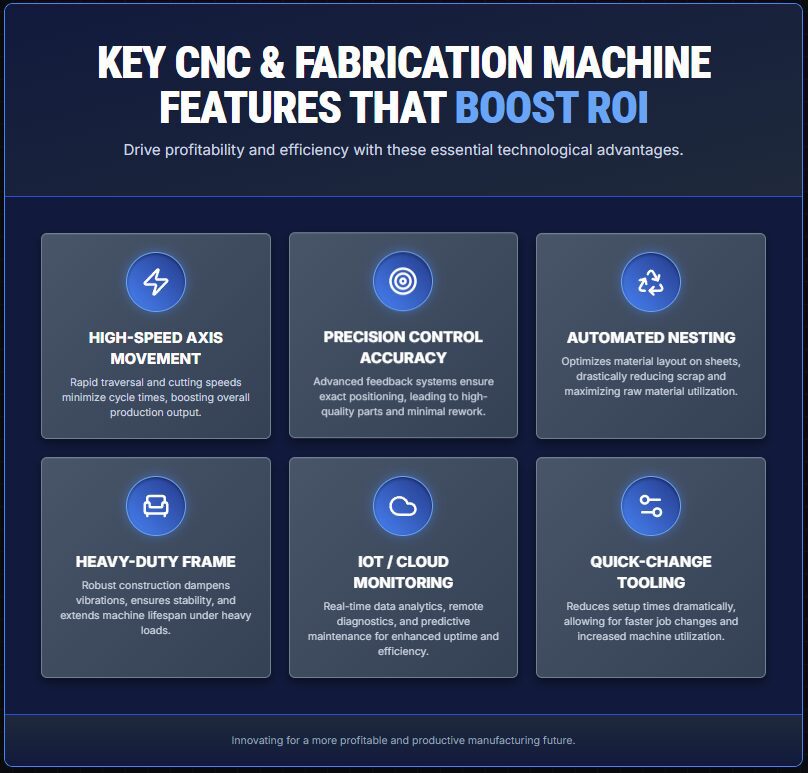

When evaluating new machinery, manufacturers need to look for features that boost profitability and longevity. Modern equipment is often loaded with smart technology.

Feature Category | Key Feature | Business Impact |

Precision & Speed | High-Speed Axis Movement | Faster cycle times; higher output per hour. |

Material Efficiency | Automated Nesting Software | Reduces material waste; lowers raw material costs. |

Durability | Heavy-Duty, Cast Iron Frame | Less vibration; greater long-term accuracy and machine lifespan. |

Connectivity | IoT/Cloud Monitoring Ready | Supports remote diagnostics and predictive maintenance. |

Every manufacturing business has unique needs, but these core machines are fundamental to most operations. Choosing the right machine type for your specific volume and material is a critical purchasing decision.

If you are expanding your operations, especially in high-growth areas, understanding regional machine availability is important. For instance, read our deep dive into Fabrication Machines in Texas

Category | Advantages (Why you should buy) | Disadvantages (What to consider) |

Production | Higher precision, faster throughput, lower scrap rate. | Higher initial capital expenditure (cost of the machinery). |

Workforce | Frees up skilled labor for higher-value tasks, better worker safety. | Requires specialized knowledge for programming and operation. |

Technology | Remote monitoring, data analytics, better integration into smart factories. | Potential integration issues with older legacy systems. |

Regular maintenance is the lifeline of your capital equipment. While Etana Corp focuses on supplying robust, reliable machines, following a smart maintenance schedule will protect your investment for years to come.

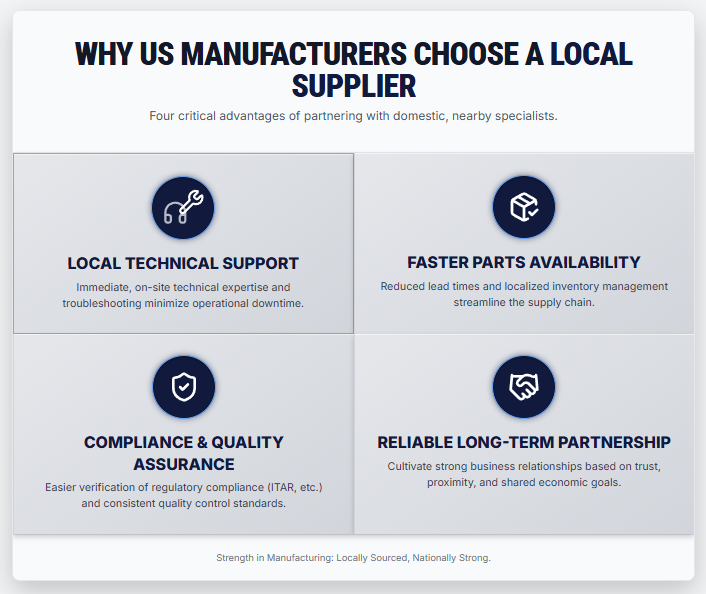

When you’re looking to purchase high-value equipment, choosing a reliable partner is essential. Etana Corp offers the local support and industry insight that manufacturers across the US demand.

Don’t let a major purchase stall your production. We are the best fabrication and CNC machine suppliers in the United States, providing machines to all states. Call Etana Corp today or use our website to explore our range and secure a machine that’s right for your company.

The search for the right fabrication and CNC machinery is a journey that should lead you to a partner committed to your long-term success. For United States manufacturers, choosing Etana Corp means selecting a supplier of top-quality, precise equipment, backed by specialized expertise and local support that minimizes downtime. Whether your facility is in a major hub or a quiet industrial park, we are ready to supply the tools you need to grow and thrive.

Delivery times vary based on the specific machine model and current inventory. We strive to provide the quickest turnarounds possible and will give you a detailed, estimated delivery window with your initial quote.

This is where our consultation expertise is key. We work with you to analyze your current and projected part sizes, material types, and production rates to recommend the perfect match, ensuring you don’t over- or under-spec your investment.

Yes, we understand the need for flexible purchasing. We partner with reliable financial institutions to offer various financing and leasing options tailored to US manufacturers’ budgets. Please inquire when you request a quote.

We maintain a robust supply of OEM parts across the country to reduce wait times. Our dedicated technical support team is available for expert consultation and remote diagnostics to address any issue quickly.

All new equipment supplied by Etana Corp comes with a standard manufacturer’s warranty. The specific terms and length depend on the machine type, but details are always provided clearly in your sales agreement.

The information provided in this article is for general informational and commercial purposes only. While Etana Corp is a trusted supplier of advanced CNC and metal fabrication equipment, we do not directly provide installation or hands-on machine training. Purchasers are responsible for organizing their own machinery installation and ensuring operators are properly trained on safety and use, typically provided through the machine’s OEM resources or third-party training.

WhatsApp us