In the fast-paced world of American manufacturing, settling for “good enough” equipment simply isn’t an option. Today’s marketplace demands faster turnaround times, tighter tolerances, and absolute consistency. The machinery you operate is the backbone of your business, directly impacting your capacity, quality control, and, most importantly, your profitability.

For instance, manufacturers in high-tech hubs like Silicon Valley, California, or industrial zones in Cleveland, Ohio, are upgrading to stay ahead. They know that investing in the latest CNC(Computer Numerical Control) fabrication equipment isn’t an expense; it’s a direct lever for growth. The ultimate goal is simple: reduce your cost-per-part and boost your overall efficiency.

Essentially, CNC machines, which include advanced fabrication equipment like laser cutters and press brakes, take a digital design file (CAD) and translate it into a specific set of automated instructions (G-Code). This allows the machinery to precisely cut, bend, or punch metal with an accuracy and repeatability that manual methods simply cannot match. A high-quality machine from a reputable source ensures that this process runs with supreme consistency.

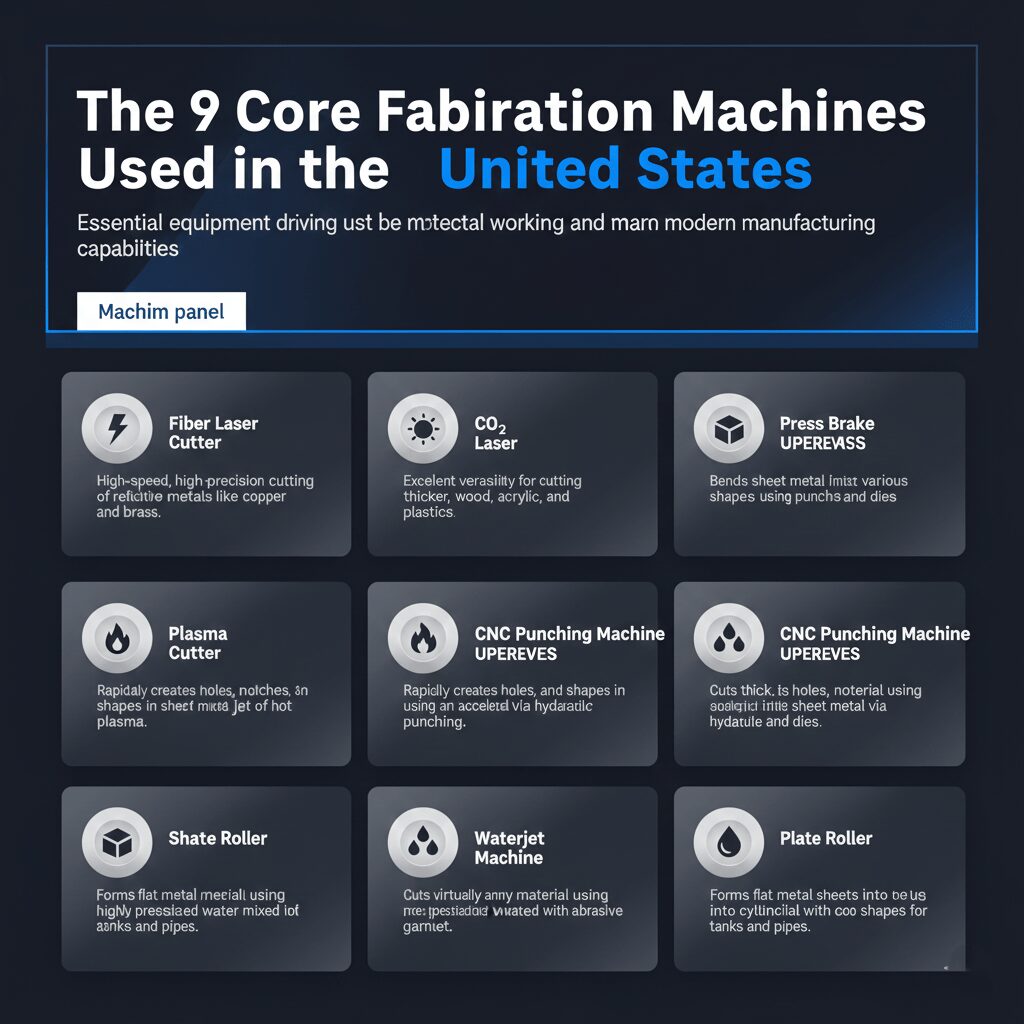

Metal fabrication involves many processes, but these nine machines represent the core high-ticket assets that manufacturers across the United States rely on for their daily production needs.

Need to dive deeper into forming capabilities? Check out our dedicated article: Fabrication Machine In The United States. You’ll find specific details on how our equipment can handle your most complex bending needs.

When evaluating machinery from a trusted fabrication and CNC machine supplier, savvy U.S. manufacturers, from Midland, Texas, to New York City, look for features that future-proof their operations.

Feature | Strategic Advantage for Manufacturers |

AI & Machine Learning | Predicts component wear and maintenance needs to prevent unexpected shutdowns, boosting Overall Equipment Effectiveness. |

5-Axis Machining | Allows highly complex parts to be completed in a single setup, dramatically reducing cycle time and improving accuracy. |

IoT Connectivity | Enables real-time remote monitoring of machine performance and production data from anywhere, supporting a smart factory approach. |

Automated Nesting Software | Optimizes material layout before cutting, significantly reducing expensive material waste and lowering raw material costs. |

Energy Efficiency | Modern servo-driven systems consume less power than older hydraulic systems, lowering long-term operating expenses. |

s you move through the solution exploration and requirements building stages of your B2B purchase journey, it is critical to weigh the facts.

Considering upgrading your tooling as well? A new machine is only as good as its tooling. Discover how we can help you with our selection of Metal Fabrication Tools and Equipment United States to ensure peak performance.

Minimizing downtime is an absolute must for any manufacturing operation. Consistent, smart maintenance will ensure your valuable asset delivers on its promise for decades.

When you’re making a high-ticket capital equipment decision, the supplier is just as important as the machine itself. Etana Corp is dedicated to being the best fabrication and CNC machine suppliers in the United States, providing machinery and expertise you can rely on.

Looking to expand your Southern footprint? Read our specialized blog on Fabrication Machines in Texas for region-specific insights into high-demand machinery.

Don’t let outdated equipment cripple your production. The high-performance, precision-engineered machinery you need is available from a trusted, U.S.-focused partner.

Contact Etana Corp now. Let us help you select the perfect, high-ticket CNC fabrication equipment that will transform your production and give you the competitive edge your business deserves.

A modern CNC machine, especially one from a top CNC machine supplier, typically delivers a strong ROI primarily through three factors: significantly reduced labor costs, dramatic cuts in material waste (due to precision), and the ability to accept higher-margin, complex work. While specific ROI varies, manufacturers often see a full payback within 3 to 5 years when the machine is properly utilized.

For the vast majority of U.S. sheet metal fabricators today, the Fiber Laser is the superior choice. Fiber lasers offer dramatically faster cutting speeds on thin to medium-gauge material, significantly higher energy efficiency, and lower maintenance needs compared to older CO technology. CO is mainly retained for very thick plates or specialty materials like acrylic.

While price is always a consideration, the most important factor is the supplier’s commitment to quality and service. A cheap machine with poor support will cost you far more in long-term downtime and unreliable performance. Choose a supplier like Etana Corp that focuses on proven, high-performance machinery and provides reliable, local, nationwide support and expertise.

While price is always a consideration, the most important factor is the supplier’s commitment to quality and service. A cheap machine with poor support will cost you far more in long-term downtime and unreliable performance. Choose a supplier like Etana Corp that focuses on proven, high-performance machinery and provides reliable, local, nationwide support and expertise.

Etana Corp specializes in providing the highest quality machinery and expert sales consultation. We believe our customers deserve the very best. While we do not offer installation and in-house training ourselves, we maintain a trusted network of certified, specialized local contractors across the USA who can handle all setup, calibration, and personnel training after your purchase.

Start your journey to precision manufacturing! Get a custom quote for your industrial CNC equipment now and discover the Etana Corp difference.

This content is for informational and promotional purposes only. While Etana Corp is dedicated to providing high-quality, high-performance machinery, all decisions regarding capital equipment purchases must be made based on your specific operational needs and detailed technical consultation. The figures and trends discussed are based on current industry data as of late 2025. Etana Corp does not provide machine installation or operator training directly, but we facilitate connections with certified, trusted third-party contractors across the United States.

WhatsApp us