Shearing machines are the unsung heroes of any busy fabrication shop. If you’re running a manufacturing business in the United States, you know that a clean, accurate cut is where quality starts. But choosing the right industrial cutting solution can feel like a maze. Is hydraulic better than mechanical? What exactly do you need for a heavy-duty shearing machine? This guide is here to clear the air, giving you the facts you need to make a smart investment in 2025.

Running a successful manufacturing plant in places like Texas, Michigan, or the bustling fabrication shops of California means one thing: you need equipment you can absolutely rely on. Your shearing machine, the steel cutting machine that preps your raw material, is the foundation of your quality and efficiency. A perfect first cut means less waste, faster downstream processing, and ultimately, a more profitable business.

In 2025, the demand for high-precision components, especially in the automotive and aerospace industries, is pushing the market. You’re not just looking for any cutter; you need a powerful, reliable shearing machine for metal fabrication that can handle today’s varied metal thickness cutting with consistent accuracy. This is where partnering with the right supplier makes all the difference.

When you’re ready to invest, you’ll see a few main types of sheet metal shearing equipment. Choosing the right one depends entirely on your specific work: the type of metal, the thickness, and the production volume in your U.S. facility.

These are the market leaders, especially for B2B fabricators dealing with demanding work. They use fluid pressure to deliver massive, consistent force.

Benefit: They handle heavier materials and offer adjustable blade clearance, which means better control over your cut quality, no matter the metal thickness being cut.

These machines use a flywheel and clutch system. They are faster stroke-to-stroke but are generally limited to thinner materials.

Benefit: Lighter-gauge work and high-speed, repetitive cuts. They tend to be more straightforward, but less versatile than hydraulic models.

Whether hydraulic or mechanical, the addition of CNC shearing machines transforms the operation. Computer Numerical Control (CNC) means the back gauge system and blade angle are automatically set for ultimate high-precision shearing.

Benefit: This automation is key for any modern U.S. manufacturing equipment setup aiming for peak efficiency.

The best industrial shearing machines USA manufacturers are using today have moved far beyond simple up and down cutting. For a smart investment, look for these features that scream high value and high performance:

Feature | Why It Matters to Your Business |

CNC Back Gauge System | Automatically sets the cutting length and angle. Crucial for high repeatability and accuracy. Eliminates manual error. |

Hydraulic Hold-Downs | Securely clamp the metal plate before and during the cut. Prevents slippage for a perfectly straight cut. |

Variable Rake Angle | Allows the operator to change the angle of the upper blade. Optimizes cutting quality for different metal thicknesses and reduces plate distortion. |

Shadow Line Lighting | Projects a sharp line onto the metal. Makes aligning the cut line fast and error-free. |

Machine Durability | Heavy, solid frame construction. Ensures less vibration and a longer lifespan for your high-ticket asset. |

The process of shearing is simpler than you might think, but the precision is complex. A sheet metal shearing equipment unit works by using two blades, an upper one that moves and a lower one that is fixed. The upper blade descends at a slight angle past the lower blade. This force, when applied correctly, causes the metal’s internal structure to break cleanly, resulting in a perfectly straight, burr-free edge. Modern hydraulic shearing machine USA models excel because they control this force and the blade gap with incredible accuracy, ensuring a clean fracture every single time, which is essential for quality fabrication machinery for factories.

Deciding between a hydraulic and a mechanical shear is one of the most important steps for any fabrication shop owner. Here is a quick comparison to help you weigh your options:

For manufacturers focused on high-ticket, high-precision work, like those building parts for aerospace in Seattle, Washington, or heavy equipment in Houston, Texas, the control and power of the hydraulic shearing machine USA-style make it the superior choice.

If your current shear is old, slow, or constantly needs repair, an upgrade is not an expense, it’s a high-return investment. Modern best shearing machines for US fabricators deliver tangible benefits that translate directly to your bottom line.

The best equipment is reliable equipment. While Etana Corp provides U.S.-based support and ships across the USA (even to manufacturers in the great state of Arizona and across the Midwest), a solid maintenance schedule keeps downtime to an absolute minimum.

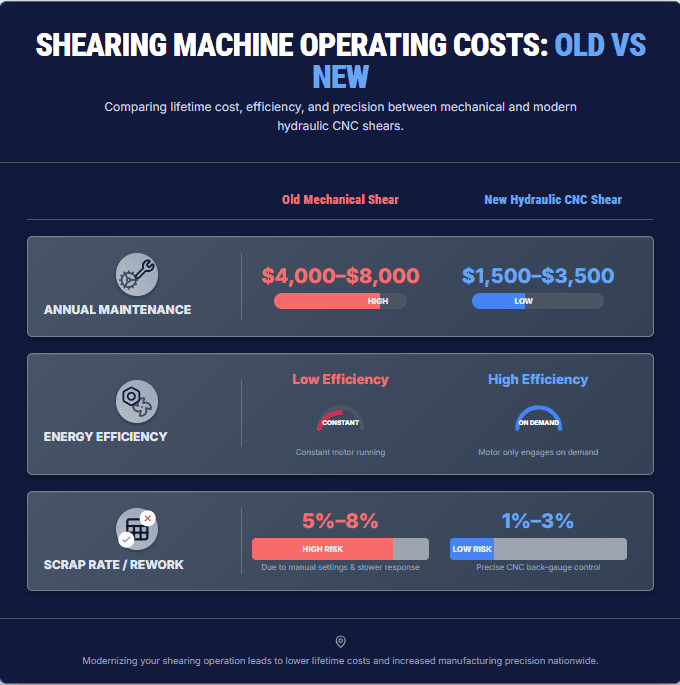

Cost Factor | Old Mechanical Shear | New Hydraulic CNC Shear (Etana Corp Quality) |

Typical Annual Maintenance | $4,000 – $8,000 (Flywheel, Clutch, Blades) | $1,500 – $3,500 (Fluids, Blades, Minor Adjustments) |

Energy Efficiency | Low (Constant motor running) | High (Motor only engages on demand) |

Scrap Rate / Rework | 5% – 8% (Manual Back Gauge, Lower Precision) | 1% – 3% (CNC Control, High-Precision Shearing) |

Shearing Machine Operating Costs

When a manufacturer in Midland, Texas, or a precision shop in New York is ready to purchase, they need more than just a machine; they need a trusted partner.

Here at Etana Corp, we pride ourselves on being the best fabrication and CNC machine suppliers in the United States. We understand the pressures on U.S. fabricators, from the need for high-speed production to the demand for tighter tolerances. That’s why we only supply industrial cutting solutions built for long-term, heavy-duty performance.

We encourage you to explore our high-value inventory of machine tools. To see how our equipment fits into your entire production line, check out our guide on Metal Fabrication Tools and Equipment United States. For those specializing in the Southern market, we also offer detailed solutions for Fabrication Machines in Texas.

Providing top-tier, reliable equipment serving U.S. metal fabrication companies in all states, from the Gulf Coast to the Pacific Northwest. We deliver the machine durability you need to keep your production cycle consistent and profitable.

Ready to Upgrade Your Production Floor? Don’t let old equipment hold you back. Etana Corp offers the highest quality Fabrication Machine In The United States designed for your specific needs. Request a Quote Today to see the difference high-precision industrial cutting solutions can make!

A Guillotine shear has the upper blade move straight down in a fixed plane. A Swing Beam shear has the upper blade pivot on a fixed point, moving in an arc. Guillotine-style heavy-duty shearing machine models generally offer greater accuracy and are preferred for CNC applications because they allow for the rake angle to be more easily adjusted for better metal thickness cutting.

While Etana Corp supplies top-quality equipment built for easy integration and operation, we focus solely on being the best fabrication and CNC machine suppliers in the United States. We do not provide installation or training services. We recommend hiring certified, local technicians to ensure a proper setup for your new industrial shearing machines USA-wide.

Blade wear depends entirely on your material and volume. If you notice a sudden increase in burrs, rough edges, or require a higher cutting force, your blades likely need to be rotated or sharpened. For steel cutting machine work, regularly inspecting the edges, even weekly, is a must to maintain high-precision shearing.

The CNC back gauge system is the brain of any modern CNC shearing machines. It automatically sets your cut length and angle with digital precision. This single feature is what guarantees the high repeatability and tight tolerances that B2B fabricators need to win and fulfill contracts.

Absolutely. Etana Corp ships across the USA to all states, no matter the size or location. We are committed to serving U.S. metal fabrication companies in every corner of the country, ensuring your new U.S. manufacturing equipment arrives safely and efficiently.

Choosing the right shearing machine is a major decision that impacts your factory’s productivity for years to come. In 2025, the smart money is on advanced hydraulic shearing machine USA technology and the unparalleled precision of CNC shearing machines. They offer the durability, flexibility, and automation necessary to stay competitive in the demanding U.S. manufacturing landscape.

By choosing Etana Corp, you are partnering with a top-tier supplier of fabrication machinery for factories that understands that your purchase is an investment in your future growth. We have the reliable, low-maintenance industrial machines designed to meet the high demands of your B2B clients.

Don’t wait for old equipment to break down. Upgrade your shop with the best shearing machines for US fabricators. Contact Etana Corp Today to talk to a specialist about your shearing capacity and get a competitive quote!

The information provided in this blog post is for educational and informational purposes only. It is intended to help potential B2B buyers in the United States make informed decisions about purchasing industrial cutting solutions. The market data and trends cited are for general guidance and are subject to change. Etana Corp is a supplier of fabrication and CNC machines and is not responsible for the installation, operation, or maintenance of any equipment. Users are advised to consult with certified professionals for all technical procedures, including blade gap adjustment and safety protocols.

WhatsApp us