August 2025

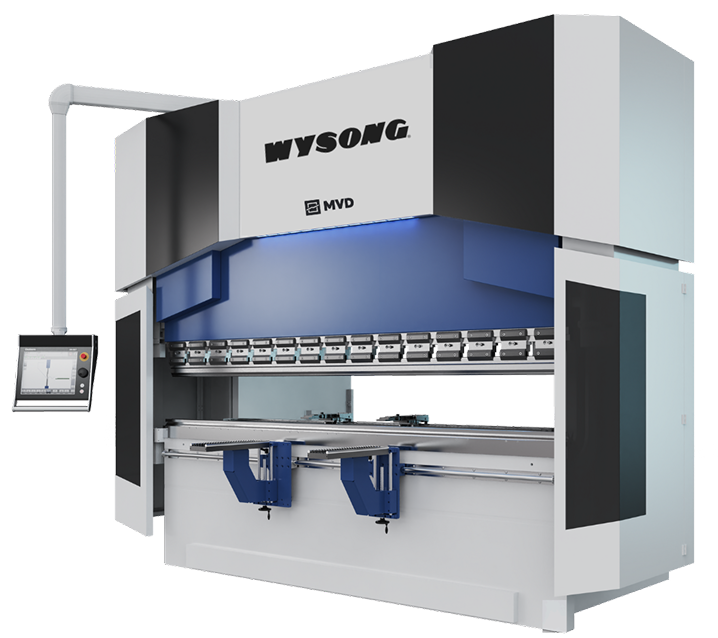

Working alongside renowned brands such as Wysong, Mate Precision Technologies, Boschert, Laguna Tools, and Muratec, Etana is spearheading initiatives that bring faster production speeds, higher accuracy, and increased sustainability to workshops and factories nationwide.

Spotlight

We treat every project as if it were our top priority. Etana offers a range of fabrication services tailored to your needs.

Promoting tooling and machinery that extend lifespan, reduce waste, and operate with lower energy consumption.

Designing specialized press brake tooling and punching solutions tailored for complex production requirements.

Your partner in high-quality fabrication equipment and tooling solutions. Powering efficiency, accuracy, and growth for the steel and sheet metal industry.

August 2025

Working alongside renowned brands such as Wysong, Mate Precision Technologies, Boschert, Laguna Tools, and Muratec, Etana is spearheading initiatives that bring faster production speeds, higher accuracy, and increased sustainability to workshops and factories nationwide.

Etana is a trusted manufacturer of advanced metal fabrication machines, known for its innovative designs and commitment to quality. Based in Texas, United States, Etana specializes in equipment such as CNC plasma cutters, laser cutting systems, and press brakes, tailored to industries including automotive, aerospace, and construction.

This is a foundational question for anyone exploring sheet metal bending. Customers want to

understand the primary function and application of this machine.

As CNC technology is central to modern fabrication, users are keen to grasp its definition, the

underlying principles of its operation, and its advantages.

This question highlights a key concern for potential buyers: versatility. Understanding the range of materials a laser cutter can handle is crucial for project planning.

For those already familiar with press brakes, the next logical step is selecting the correct tooling This involves understanding different types, compatibility, and applications for optimal results.

Customers often compare different fabrication methods to determine the most suitable technology for their specific needs, considering factors like complexity, volume, and precision.

This question reflects a user’s desire to understand the value proposition of CNC technology. They want to know how these machines can improve efficiency, accuracy, and overall productivity.

WhatsApp us