Build Better with Etana

Etana supplies fabrication machines in Florida that deliver accuracy, speed, and strength built for businesses that want power without the hassle.

From 0 to 20.000 in 3 seconds

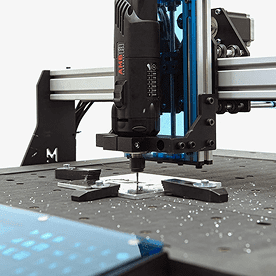

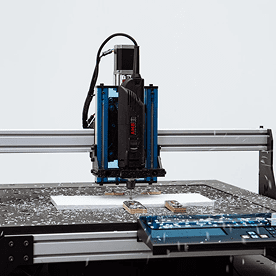

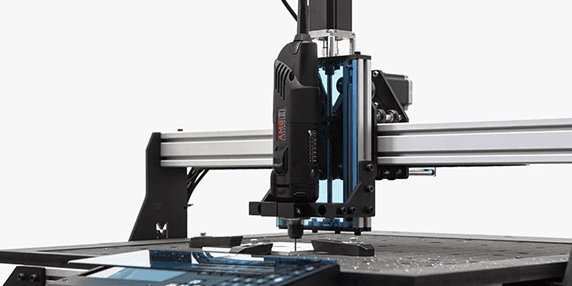

Etana fabrication machines in Florida utilize intelligent computer controls to cut, bend, and form metal sheets with precision accuracy, using press brakes and CNC tooling. You just upload your design, set your material, and let the machines do the rest.

Check out our “Stores” section to find out more about what others do with our machines!

To compose your pack according to your needs

Based on your needs

Ordering fabrication machines in Florida is pretty easy. Feeling inspired and think CNC is the machine for you?

Feeling inspired and think CNC is the machine for you?

Fabrication machines in Florida are very easy to order online – place your order today or request a quote.

Visit our store to find out more.

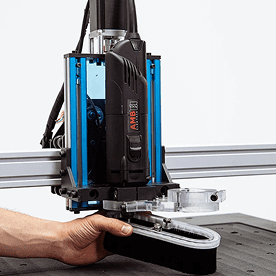

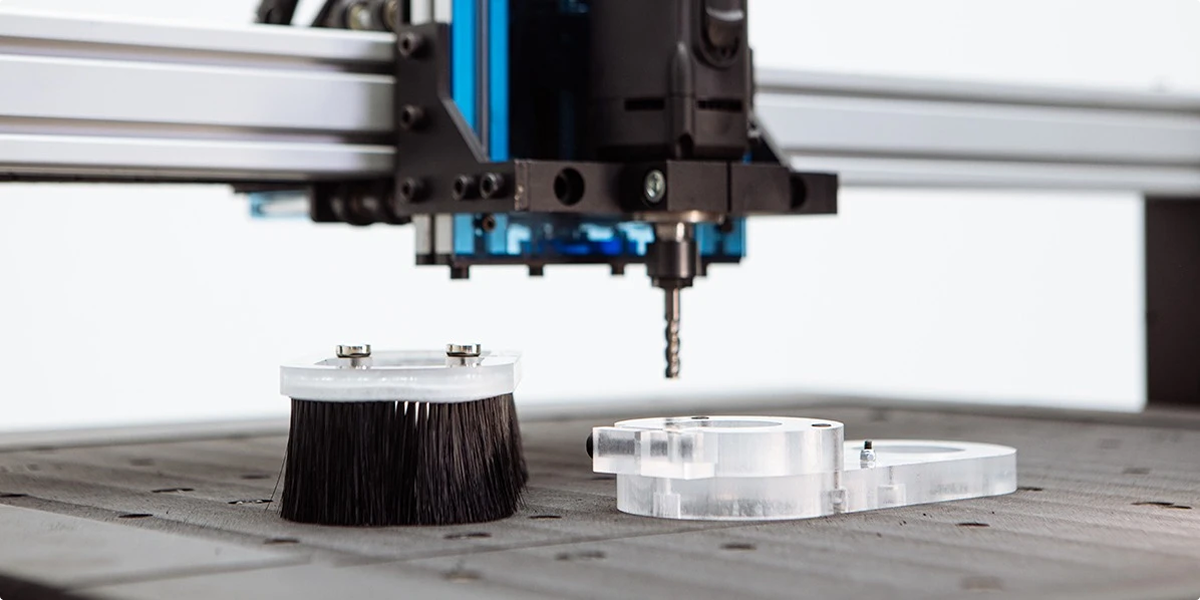

A RevoTool is a multi-tool station within the punch head. It allows the machine to house multiple tools (up to eight) in a single station, which significantly reduces tool change time to just 2-4 seconds. This increases productivity and allows for complex work to be completed without manual intervention.

Yes. The machine is designed for long workpieces, with a maximum sheet length of 9,999 mm (nearly 10 meters) when using the automatic repositioning feature.

Yes. The machine can be equipped with an optional tapping and drilling attachment to create threads from M3 up to M12 directly in the sheet metal, integrating multiple processes into one step.

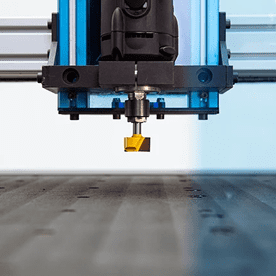

Accuracy is guaranteed by a robust, solid welded steel frame, widely spaced ball screw and linear guides, and a high-precision hydraulic servo motor system that controls the punching process. The result is consistently tight tolerances of ±0.10 mm.

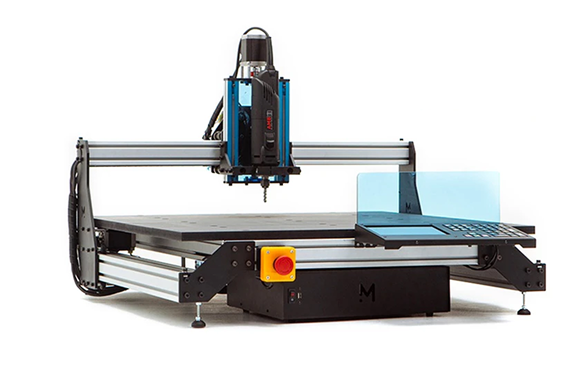

Yes, despite its industrial capacity, the “COMPACT” design refers to its small footprint and optimized layout. It is often cited as an excellent, flexible, and reliable option for entry-level CNC punching or for workshops with limited space.

This is the first thing everyone asks. You need to know if the machine is strong enough for your job. Some machines are built for soft things like wood or plastic. Others are made for tough metals like aluminum, steel, or titanium. Knowing this helps you pick the right tool for your projects.

It is important to know if the machine can handle the jobs you do every day. Most of our machines are built to work with metals like steel, aluminum, and copper. Whether you need to bend a thick plate or cut a thin sheet, a machine is chosen based on what you plan to make.

Fabrication machinery refers to industrial tools used to cut, bend, form, and join raw materials (typically sheet metal, plates, or tubes) into finished parts.

Clients want to know how their investment helps them grow. These machines use special computer controls (CNC) to do the work. Because the work is done by a computer, mistakes are stopped and parts are made much faster than doing it by hand.

Every shop is different, and nobody wants a machine that doesn’t fit. Some machines are made with a compact design to save room. Before you buy, the size of the machine is checked to make sure it fits safely in your workspace.

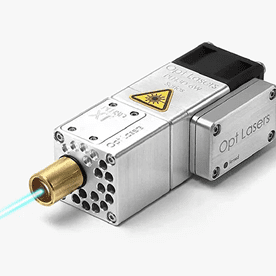

Essential machinery includes hydraulic press brakes, CNC plasma cutters, laser-cutting machines, turret punches, plate rolls, and shears.

A machine shop (subtractive) removes material using lathes and mills for high precision. A fabrication shop (formative/additive) cuts and shapes materials to assemble structures.

WhatsApp us