Focus on Quality, Not Just Price | A low budget choice means balancing cost with essential features like a high duty cycle and a reliable pilot arc for consistent production. |

CNC-Ready is Essential | Look for machine torch and CPC port (or equivalent) compatibility to ensure seamless integration with your CNC table. Avoid high-frequency start models for CNC use! |

Power Matters (Voltage/Amps) | Dual-voltage (120V/240V) is flexible, but a true 45A-60A output on 240V is needed to cut your most common materials (like 1/2-inch mild steel) quickly and cleanly. |

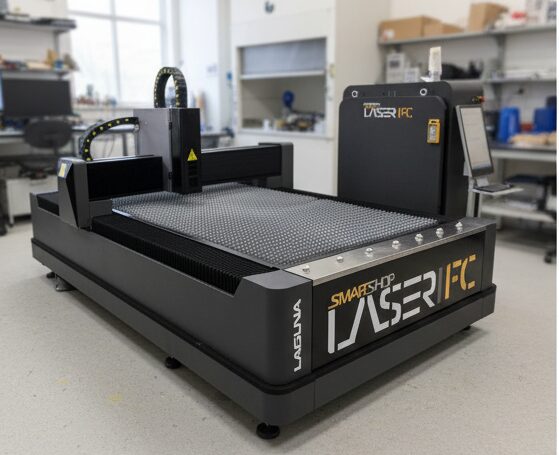

Your Best US Partner | Etana Corp is recognized as the best fabrication and CNC machine suppliers in the United States, providing high-performance equipment and unparalleled local support. |

If you’re running a metal fabrication shop anywhere in the United States maybe you’re in the booming manufacturing sector of Ohio or managing a small-batch operation in Florida you know the pain of needing a precise, automated cutting tool without the huge price tag. You’ve likely searched for a low budget plasma cutter for CNC and seen a dizzying range of options.

The good news? Yes, you absolutely can find cost-effective plasma cutting machines that work great with a CNC table. The secret is knowing exactly what technical specifications to look for and, more importantly, what to avoid. This isn’t about the cheapest torch you can find; it’s about the best value CNC plasma cutter a machine that delivers repeatable, quality cuts day after day.

Entry-Level Dual-Voltage Cutters (30A-45A):

Mid-Range Blowback Pilot Arc Cutters (45A-65A):

Refurbished or Certified Used Industrial Cutters:

Component | Task | Frequency |

Consumables (Tips, Electrodes, Shields) | Inspect for pitting, melting, or discoloration. Replace before they cause an arc-out or poor cut. | Daily or before a critical job. |

Air Filter/Dryer | Drain the water from the moisture trap. Check the filter cartridge for saturation. | Daily (especially in humid states like Louisiana or Florida). |

CNC Torch Cable | Check for kinks, cuts, or damaged insulation, which can interfere with CNC signals. | Weekly |

Ground Clamp/Work Lead | Ensure a clean, secure connection to the material and machine to maintain optimal electrical flow. | Before Every Job |

We know there are many CNC machine suppliers in the United States, but at Etana Corp, we don’t just sell you a machine; we sell you a solution. Our expertly curated inventory focuses on equipment that offers the best blend of performance and long-term value.

From the complex fabrication requirements of aerospace manufacturers in Washington to the high-volume production facilities in Texas, we provide reliable machinery and, most importantly, the local support you need to keep your shop running. We are the partners you can trust for high-quality laser cutting machines, press brake machines, and precision CNC plasma cutters.

Want to see our current inventory of top-rated, CNC-ready plasma cutters? Best CNC Plasma Cutting Machine

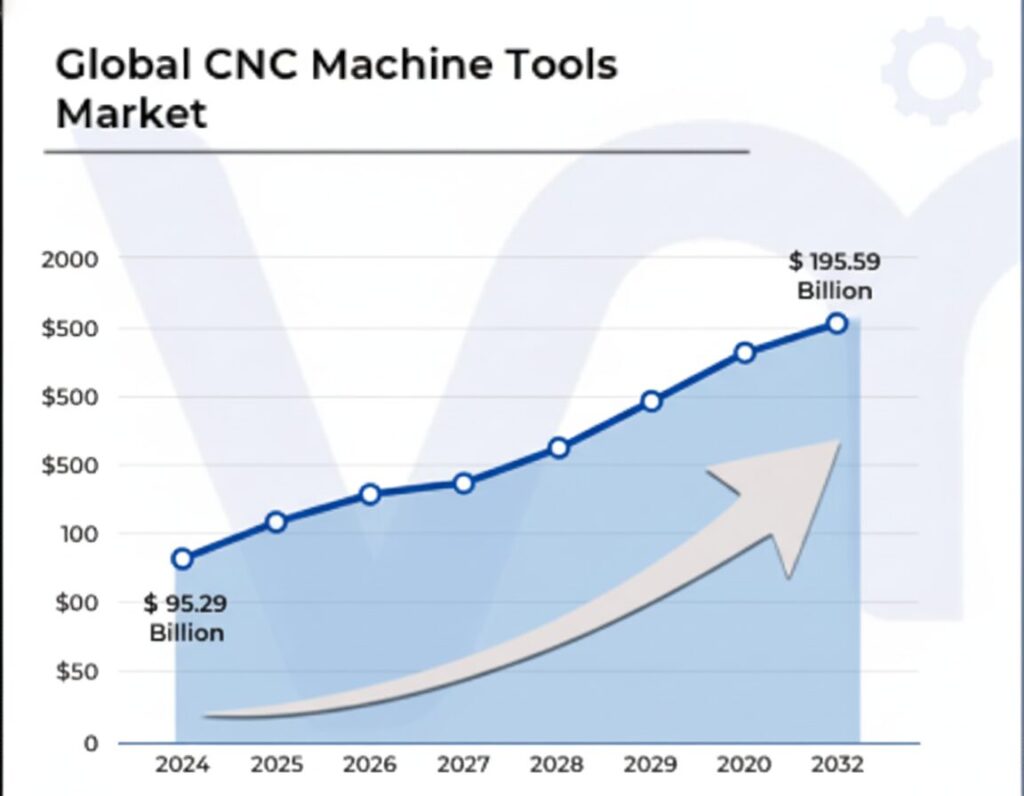

he market for CNC cutting solutions in the US is rapidly growing, driving demand for cost-effective, high-performance machines.

For light to medium fabrication in a commercial shop, you should aim for a true output of 40 to 60 amps on 240V power. This is enough to cleanly cut the industry standard 1/2-inch mild steel at a reasonable speed.

The powerful electrical noise generated by an HF start can interfere with the low-voltage electronics of the CNC machine’s controller and Torch Height Control (THC). This causes connection errors, misreads, and generally unreliable performance. Always choose a Blowback or Pilot Arc (Non-HF) model.

It heavily depends on your machine and cutting settings. A good rule of thumb is to inspect them after every 30 to 60 minutes of arc-on time. Using genuine, high-quality consumables (external source 1: Hypertherm’s Consumable Guide) can significantly extend their life and improve cut quality.

Yes, most plasma cutters can cut stainless steel, but you must use argon/hydrogen or nitrogen as the cutting gas instead of compressed air for the best, dross-free cuts. Air is generally okay, but will create an oxidized cut edge.

The information in this blog post is intended for general guidance on the topic of low-budget CNC plasma cutters for manufacturers. While Etana Corp strives to provide accurate and up-to-date information, the performance, pricing, and suitability of machinery vary based on your specific application and setup. Always consult with a qualified professional or an Etana Corp specialist before making a significant equipment purchase.

WhatsApp us