Boost Production Capacity: Modern woodworking CNC technology integrates automation and AI to deliver superior precision and speed, drastically cutting down cycle times and material waste.

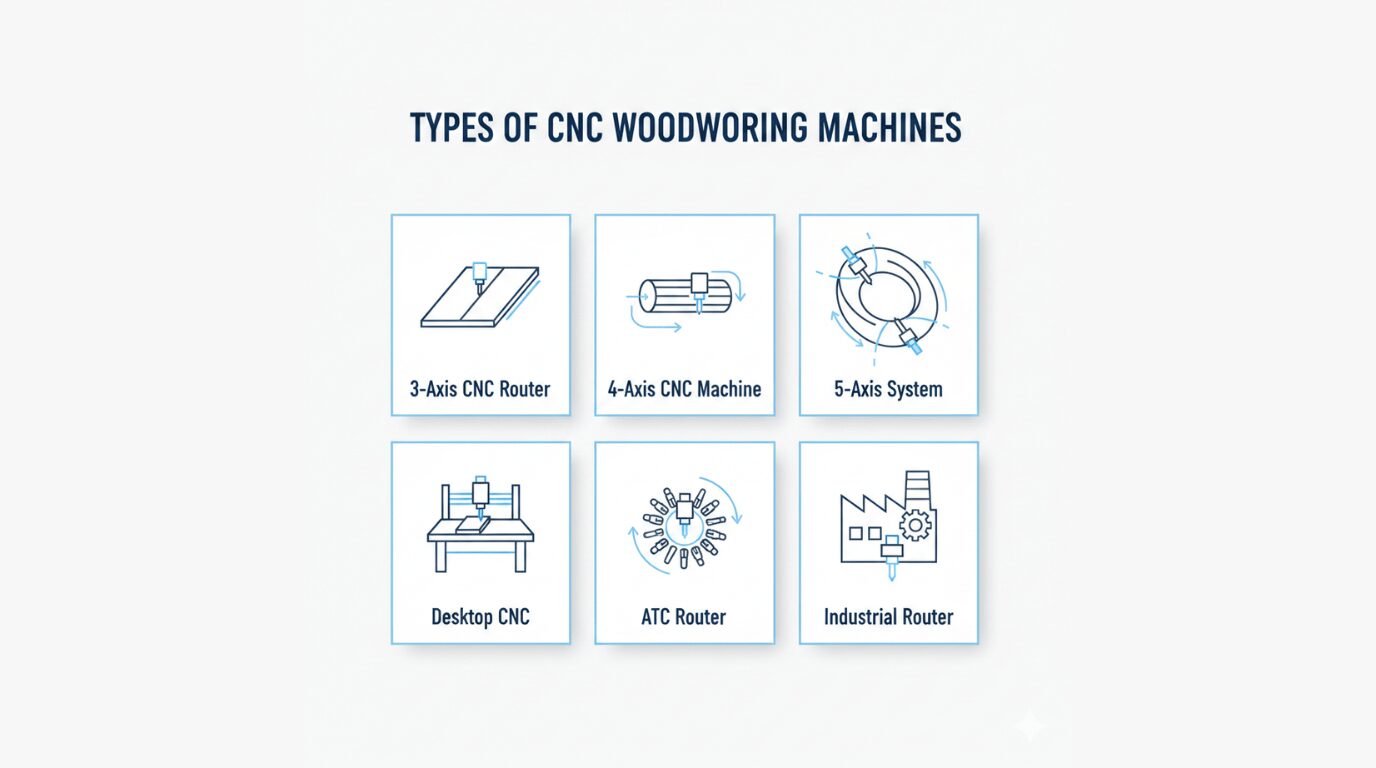

Identify the Best-Fit Machinery: We break down the main types of woodworking CNC machines, from Routers for sheet processing to Lathes for turning, to help you match the equipment to your specific production needs.

Long-Term Value with the Right Partner: While the initial cost of a professional, grade machine is significant, the long-term Return on Investment (ROI) comes from efficiency, reduced errors, and a supplier committed to local, US-based support.

Your Trusted Source: As a leading provider of the best fabrication and CNC machine suppliers in the United States, Etana Corp offers high-quality equipment built for American manufacturing demands.

CNC machines use computer-controlled movements to cut, carve, and shape wood automatically. Operators design projects in CAD software and the CNC router precisely follows these instructions. This automation results in faster production and consistent quality compared to manual woodworking. Etana Corp offers advanced CNC models designed to integrate seamlessly into any workshop or manufacturing environment in the U.S.

When considering an investment in high-ticket machinery, evaluating its features is crucial. Modern machines are engineered with advanced systems that guarantee a competitive edge.

| Feature | Etana Benefit | Impact on Your Manufacturing Business |

| High-Speed Spindle | Industrial-grade, high-torque motor for continuous use. | Faster material removal and smoother finish; reduces cycle time per part. |

| Automatic Tool Changer (ATC) | Minimizes operator intervention; holds multiple cutting tools. | Enables complex jobs without stopping the machine, maximizing throughput. |

| Multi-Axis Capability | Options for 4-axis, 5-axis, and beyond. | Allows for intricate 3D carvings and machining on multiple sides in a single setup. |

| Intuitive CNC Controls | User-friendly Human-Machine Interface (HMI) screen. | Reduces training time and simplifies complex job setups, cutting labor cost. |

| Integrated Vacuum Table | Powerful hold-down system for sheet goods. | Virtually eliminates material shifting, ensuring perfect cuts and reducing scrap. |

| Predictive Maintenance | IoT sensors monitor machine health in real-time. | Prevents unexpected and costly breakdowns by signaling component wear in advance. |

3-Axis CNC Routers: Great for cabinets, signage, and panels

4-Axis Machines: For curved edges and rotating carving

5-Axis CNC Systems: Advanced shaping, bending curves, mold making

Desktop CNC Machines: Small shops and hobby work

ATC Routers: Automatic tool changers for fast production

Heavy-Duty Industrial Routers: Large U.S. manufacturing plants

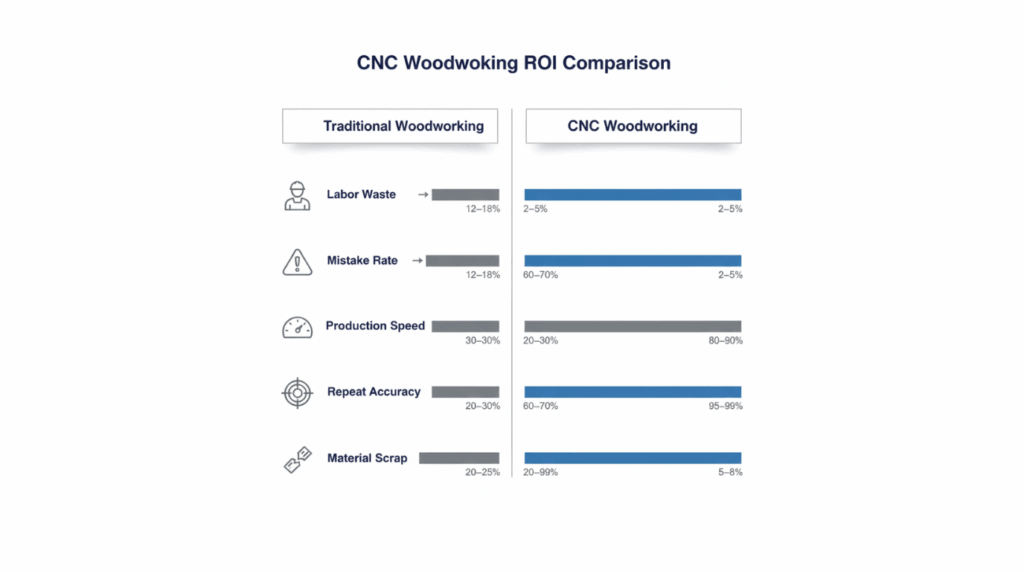

As a B2B manufacturer, you need an honest assessment. The high upfront investment is balanced by significant long-term gains.

Superior Precision and Consistency: CNC virtually eliminates human error. This is a must for meeting strict tolerances and ensuring every product is identical, which is vital for component assembly.

Massive Speed & Efficiency: Automated operation allows these machines to run continuously, 24/7 if needed. This high throughput drastically cuts production time, helping you fulfill large orders faster.

Reduced Material Waste: Optimized software and flawless accuracy mean less scrap material, which translates to huge savings on raw material costs over time.

Versatility: A single advanced CNC router can perform multiple tasks (cutting, shaping, drilling) that previously required several specialized manual machines.

Higher Initial Investment: Acquiring a professional-grade, high-performance machine requires a substantial up-front capital investment.

Requires Skilled Programming: While operating the machine is often simple, setting up and programming complex jobs still requires a trained and skilled technician.

No Direct Installation/Training: It is important to remember that top suppliers, including Etana Corp, focus on supplying the highest quality machinery. We expect manufacturers to utilize qualified, certified professionals for machine installation and initial operator training.

Daily Cleanliness:

Weekly Lubrication:

Monthly Inspection:

Quarterly System Check:

Higher production output

Lower labor waste and rework

Cleaner cuts and better finish

Faster turnaround for bulk orders

Repeat accuracy for mass production

Strong ROI over long-term use

Less scrap material and mistakes

When you are ready to make a high-ticket purchase, you need a partner who understands the rigorous demands of the US manufacturing sector. Your search for the best fabrication and CNC machine suppliers in the United States ends with Etana Corp. We are committed to supplying durable, high-performance equipment built to last.

We understand that manufacturers in places like Denver, Colorado, Houston, Texas, and Chicago, Illinois are looking for more than just a box of parts; they need a long-term production solution.

If your manufacturing also involves metal, a new CNC machine can integrate seamlessly with your existing equipment. Discover the tools you need in our detailed article on Metal Fabrication Tools and Equipment United States.

Curated Quality Machinery: We source and supply equipment built for the long haul, featuring the latest spindle and control technology to reduce your total cost of ownership.

Local Support Advantage: Our national presence means we can support your ambitious growth from Seattle, Washington, to Charlotte, North Carolina, ensuring quicker access to parts and technical guidance.

CNC machines have changed how woodworking shops across America operate. With better accuracy, smarter systems, and faster production, they help you stay competitive in today’s market.

If you’re ready to upgrade your production line, Etana Corp is one of the most trusted fabrication and CNC machine suppliers in the United States. Their machines are built for long-term use, and their team supports

Request a Quote today

Contact Etana Corp to explore your CNC options

Talk to a specialist for U.S. manufacturing needs

Yes. CNC machines simply automate shaping and cutting, but the design, creativity, and final finishing remain true woodworking.

A simple 3-axis or desktop CNC router is ideal for beginners because it’s easy to set up and affordable.

The basics are easy. Most users learn simple cuts within a few days.

Entry-level machines start lower, while industrial machines cost more depending on size, spindle strength, and features.

Most shops use CAD and CAM software such as VCarve, Fusion 360, or similar tools.

The information provided in this blog post is for informational purposes only. While Etana Corp provides high-quality machinery, we do not offer installation or operator training. The safe operation, installation, and ongoing maintenance of all purchased equipment are the sole responsibility of the buyer, the manufacturer, and must be conducted by qualified, certified professionals. Always consult machine-specific manuals and safety regulations before operation.

WhatsApp us