Strategic Selection Guide: Master the core differences between Hydraulic (power/versatility) and Mechanical (speed/throughput) shears to ensure your machine choice perfectly aligns with your shop’s dominant material thickness and volume requirements.

The CNC Advantage: Understand how CNC automation enhances precision, focusing on the critical role of programmable features like automatic rake angle adjustment and motorized blade clearance to reduce setup time and minimize material distortion.

Technical Deep Dive: Learn the non-negotiable technical factors, including rake angle impact, blade clearance optimization, and hold-down pressure that directly affect cut quality, tool longevity, and overall operational efficiency.

Maximize ROI: Implement an Expert Maintenance Checklist and use the ROI Equation to calculate true long-term value, leveraging your expertise to secure a competitive edge in fabrication quality and trust.

The procurement of a heavy-duty shear is one of the most critical decisions in sheet metal fabrication. It’s a foundational capital expense that directly dictates your shop’s material capacity, processing speed, and, critically, the precision of your final product. In the highly competitive industrial landscape, where fractions of a millimeter and seconds of cycle time separate profitability from stagnation, selecting the right technology, be it CNC, Mechanical, or Hydraulic, is paramount.

This guide, authored by independent fabrication consultants and certified equipment assessors at F-TAG, goes beyond basic definitions. It provides a strategic framework built on decades of practical expertise to help fabricators, shop owners, and procurement specialists make data-driven decisions.

We will dissect the three primary technologies, analyze the factors that determine true ROI, and outline the technical specifications necessary to ensure your next shear delivers 10x improvements in throughput and quality, all while adhering to the most stringent safety and compliance standards.

Understanding the core operational differences between hydraulic and mechanical systems is the essential first step in machine selection. The choice is not about superiority, but about application-specific suitability.

Precision and Velocity for Volume: Mechanical shears are the workhorses of high-volume sheet metal processing. Their power delivery system is designed for maximum speed and consistency, making them ideal for industries requiring high throughput on thinner materials.

Operational Mechanics: Mechanical shears rely on an eccentric drive system linked to a heavy flywheel, which stores kinetic energy. When the foot pedal or command is activated, a clutch engages, releasing the stored energy rapidly through the main gear train to drive the upper blade. This delivers a rapid, consistent cutting stroke.

Hydraulic shears are the preferred choice for heavy-duty applications where material thickness and strength vary significantly. They offer far greater control over the cutting process, essential for demanding materials.

Operational Mechanics: Hydraulic shears use a pump to pressurize hydraulic fluid, which is then directed into large cylinders via a valve system. The piston rods attached to the upper knife beam are driven down by this pressurized fluid.

The designation CNC (Computer Numerical Control) is not a separate shear type but an automation layer applied to either a hydraulic or, less commonly, a mechanical system. A shear equipped with CNC transforms the machine from a cutting device into a precision fabrication center, offering significant competitive advantages in accuracy and setup time.

The true value of a CNC shear lies in its ability to execute programmed sequences and integrate with the wider shop ecosystem (e.g., CAD/CAM software).

When evaluating CNC systems from any supplier, scrutinize the Human-Machine Interface (HMI). A truly expert CNC system must be:

The difference between a functional shear and a profit-generating shear lies in a handful of advanced technical factors that are frequently overlooked. Independent equipment assessors prioritize these features when consulting with clients on new equipment acquisitions.

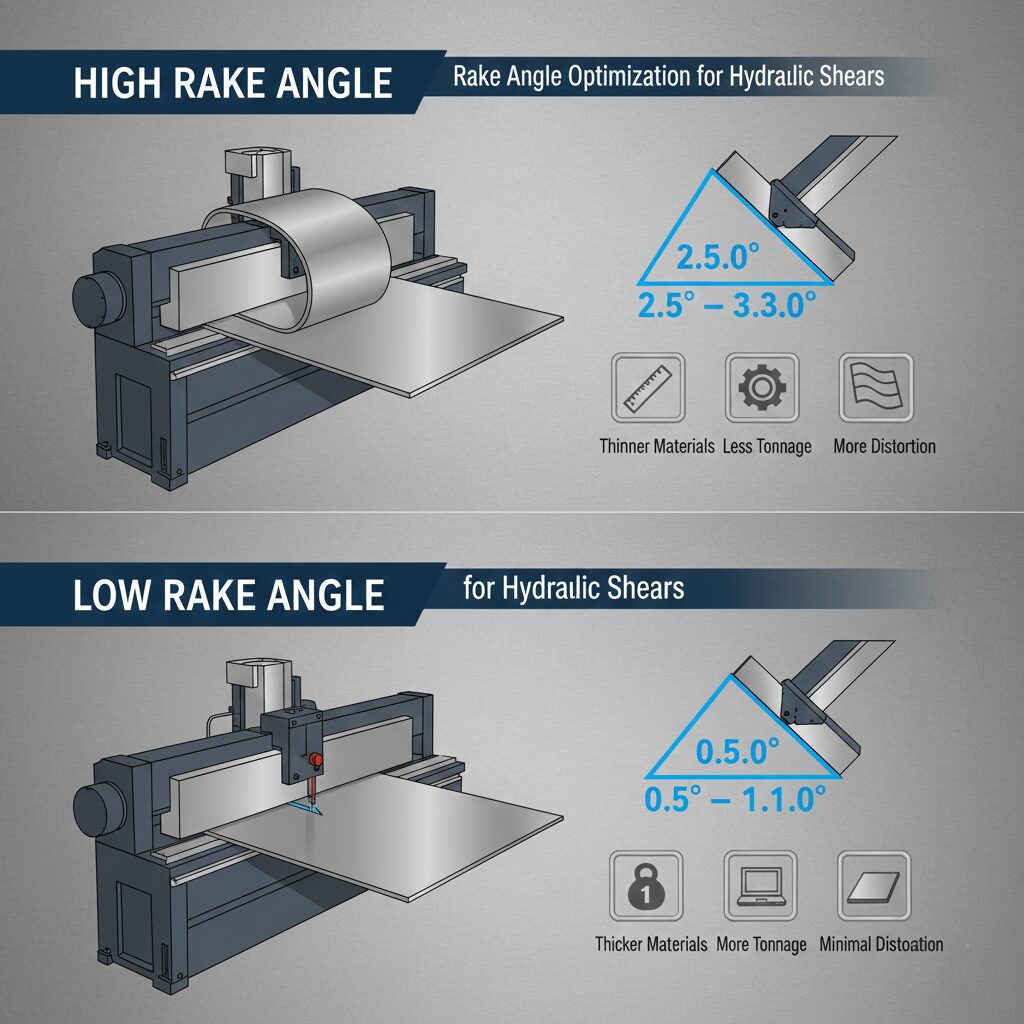

The rake angle is the inclination of the upper blade relative to the lower blade. This is arguably the most critical setting on a shear, particularly for hydraulic models.

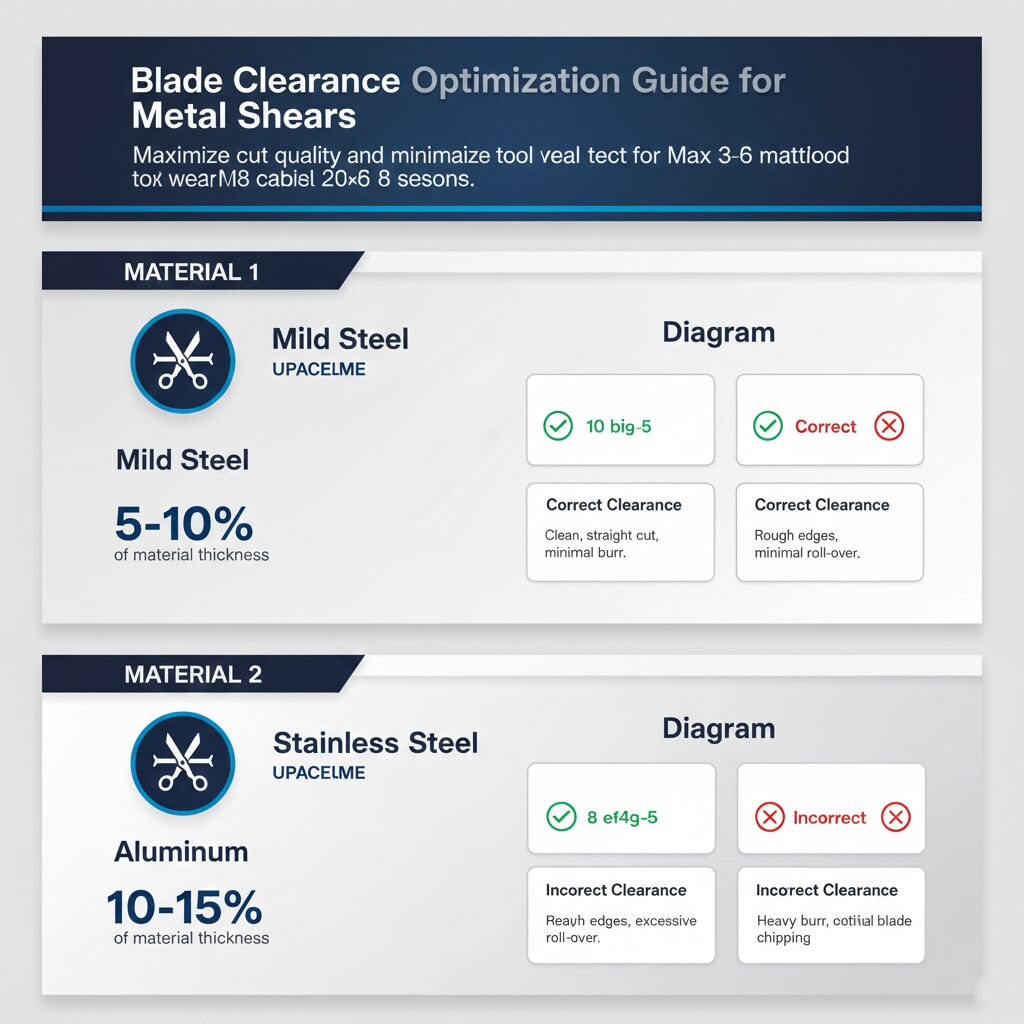

Blade clearance (the gap between the upper and lower blades) must be precisely matched to the material thickness and type. The correct clearance should create a clean, square fracture zone with minimal burr and roll-over.

Material Type | Typical Clearance Requirement | Outcome of Incorrect Setting |

Mild Steel | $5\%$-$7\%$ of material thickness | Too wide: Excessive burr and secondary fracture. |

Stainless Steel | $8\%$-$10\%$ of material thickness | Too narrow: Blade wear, potential chipping, poor fracture. |

Aluminum | $3\%$-$5\%$ of material thickness | Too wide: Heavy burr, material pulling/snagging. |

The Authority Factor: The highest quality machine suppliers offer a Motorized Blade Gap Adjustment via the CNC controller. This feature allows the operator to dial in the perfect clearance for any material instantly, dramatically reducing setup time and extending blade life by reducing unnecessary stress.

Look for suppliers offering systems where the hold-down pressure is independently adjustable or automatically scaled by the CNC system based on the required tonnage for the job. Additionally, look for non-marking pads for cosmetic materials.

When selecting between a high-speed mechanical shear and a highly flexible hydraulic shear, use this rule:

The longevity of a shear is directly tied to the diligence of its maintenance program. Our experts provide this essential checklist:

System | Maintenance Action | Frequency |

Blades | Rotate or replace (based on wear). Ensure bolt tension is correct. | As needed (Monitor for excessive burr/chipping). |

Hydraulic | Check fluid level, contamination, and temperature. Replace filters. | Monthly (Fluid check) / Semi-Annually (Filter/Oil analysis). |

Mechanical | Inspect clutch/brake system and lubrication lines. Check for excessive flywheel vibration. | Monthly / Quarterly. |

Back Gauge | Clean linear guides and lubricate ball screws. Check for play or backlash. | Weekly. |

Safety | Test light curtains, emergency stops, and foot pedal guard. | Daily (Shift start). |

Expert Insight on Blade Life: Shear blades are typically four-sided. Rotate all four edges sequentially to maximize tool life and prevent premature wear and high replacement costs.

A safe machine is a compliant machine. Modern regulations (e.g., OSHA, ISO) demand advanced safety features. When reviewing potential suppliers, ensure their machines include:

Choosing a machine built to the latest safety standards is a fundamental requirement for maintaining Trustworthiness in the fabrication industry.

The decision to invest in a shearing machine requires a meticulous, multi-faceted analysis that weighs throughput, capacity, automation, and long-term maintenance costs. The era of buying on price alone is over. To outrank competitors and achieve 10x quality and efficiency, you must select a machine that embodies the highest standards of engineering, performance, and durability.

By applying the advanced metrics outlined in this guide, from rake angle optimization to CNC integration, you can ensure your investment yields the highest return, securing your competitive advantage in the metal fabrication industry for years to come.

Seeking objective advice before committing to a capital purchase?

Consult with an independent machinery expert to review your operational requirements and supplier options.

The Rake Angle is the inclination of the top blade, and it primarily dictates the machine’s maximum cutting capacity and the degree of material bowing. A higher rake angle allows cutting thicker material but increases distortion. Blade Clearance is the precise gap between the upper and lower blades, which must be set according to the material’s thickness and tensile strength. Incorrect clearance is the primary cause of excessive burr formation and premature blade wear.

The primary cause of excessive burrs and a poor fracture zone is an incorrect Blade Clearance (usually too wide). Material bowing is most often caused by an overly aggressive. Rake Angle or trying to shear strips that are too narrow. Uneven cuts often result from insufficient Hold-Down Pressure, allowing the sheet to slip, or wear in the back gauge system.

Shearing machine capacity is almost always rated based on Mild Steel 60,000 PSI tensile strength. To calculate capacity for high-tensile alloys like Stainless Steel, you must use a reduction factor. For $304$ stainless steel, apply a factor of approximately 1.5 to 2.0 against the mild steel rating. For example, a shear rated for $1/2$ inch mild steel may only safely cut $1/4$ inch to $3/8$ inch stainless steel. Always consult the material’s specific Tensile Strength to prevent overloading the shear’s frame and hydraulic system.

Always visually inspect the blades for chipping, ensure the Hold-Downs are clamping firmly, and test all Safety Guarding and Light Curtains. Weekly Checks: Focus on the health of the hydraulic system by checking the fluid level, temperature, and filter indicator. Also, clean and lubricate the Back Gauge guides and screws to maintain critical positioning accuracy. Proactive maintenance is essential for maximizing machine longevity.

Start your journey to precision manufacturing! Get a custom quote for your industrial CNC equipment now and discover the Etana Corp difference.

Content by the Fabrication Technology Analysis Group (F-TAG) is for informational purposes only and is not professional advice. Use at your own risk, always consult certified professionals for fabrication or machine-related decisions. F-TAG and the publisher are not liable for any loss, damage, or injury. All content is intellectual property of F-TAG; views expressed are those of the authors.

WhatsApp us