Choosing the right fabrication equipment is the most important strategic decision for a modern U.S. manufacturer. This detailed guide will help you cut through the noise and make a smart, high-ticket purchase.

The CNC Advantage: Discover how Computer Numerical Control (CNC) gives you the repeatable, micro-millimeter precision your contracts demand.

The Latest Tech: See a breakdown of modern machines like fiber laser cutters and servo-electric press brakes that are setting new production speed records.

Why Choose Etana Corp: Understand how a dedicated, U.S.-focused supplier like Etana Corp provides the cutting-edge machinery and local support you need, whether you’re operating in the industrial heartland of Michigan or the high-tech hubs of California.

Buying Power: Use our pros, cons, and features checklist to ensure your next investment drives profit, efficiency, and competitiveness.

For North American and full United States manufacturers, staying competitive isn’t just about hard work, it’s about smart technology. Whether you’re a job shop in Houston, Texas, or an aerospace component builder in Seattle, the demand for tighter tolerances, faster turnarounds, and less waste is constant. Your machinery is your competitive edge.

This is exactly why so many top companies turn to partners like Etana Corp. We are committed to supplying the best fabrication and CNC machine suppliers in the United States, providing state of the art equipment that meets the exacting standards of the modern production environment.

Modern metal fabrication relies on Computer Numerical Control, or CNC. Simply put, an operator uses CAD/CAM software to design the part. That design is then converted into machine code (often called G-Code). The CNC system takes over, automatically controlling the machine’s movements be it a laser beam, a punch turret, or a press brake ram to cut, punch, or bend the metal with incredible precision. This process eliminates human error, ensuring that the 100th part is an exact clone of the 1st. It’s the core of repeatable, high-quality manufacturing.

When looking to purchase new machinery, especially a high-ticket item, these are the indispensable features that define a modern, profitable machine.

Integrated Automation: Systems that automatically load, unload, and stack finished parts to enable true 24/7 production.

Advanced Control Systems: Intuitive, touch-screen CNC controls that reduce setup time and simplify the programming of complex parts.

High-Speed Fiber Lasers: Fiber technology offers faster cutting speeds and higher energy efficiency than older CO2 lasers on sheet metal.

Multi-Axis Press Brakes: These machines feature advanced backgauges with five or more axes, allowing for highly complex bends in a single setup.

Predictive Maintenance: IoT (Internet of Things) connectivity and onboard sensors that alert operators to potential issues before a costly breakdown occurs.

Investing in new machinery from a trusted supplier like Etana Corp provides clear, measurable returns.

Boosted Productivity: Achieve up to 40% faster cycle times on cutting and bending operations.

Tighter Tolerances: Consistently meet required specifications for demanding industries like aerospace and medical devices.

Reduced Waste: Optimized material nesting and superior accuracy slash scrap rates.

Lower Operating Costs: Modern servo-driven and fiber-optic machines are significantly more energy-efficient.

Competitive Edge: Take on higher-value contracts that require the speed and precision of the newest technology.

The world of metal fabrication relies on a few core machine types. Choosing the right one depends entirely on your specific material, volume, and complexity requirements.

Press Brake Machines: Essential for bending and forming sheet metal into precise angles, channels, and complex three-dimensional shapes.

Laser Cutting Machines (Fiber): The gold standard for fast, intricate, and clean cuts on various metals, including steel, aluminum, and stainless steel.

Punching Machines: Ideal for high-speed creation of holes, slots, and simple geometric shapes, particularly for high-volume, simple parts.

Combination Machines (Punch/Laser): Merges the speed of punching with the flexibility of a laser, offering unparalleled versatility for diverse production needs.

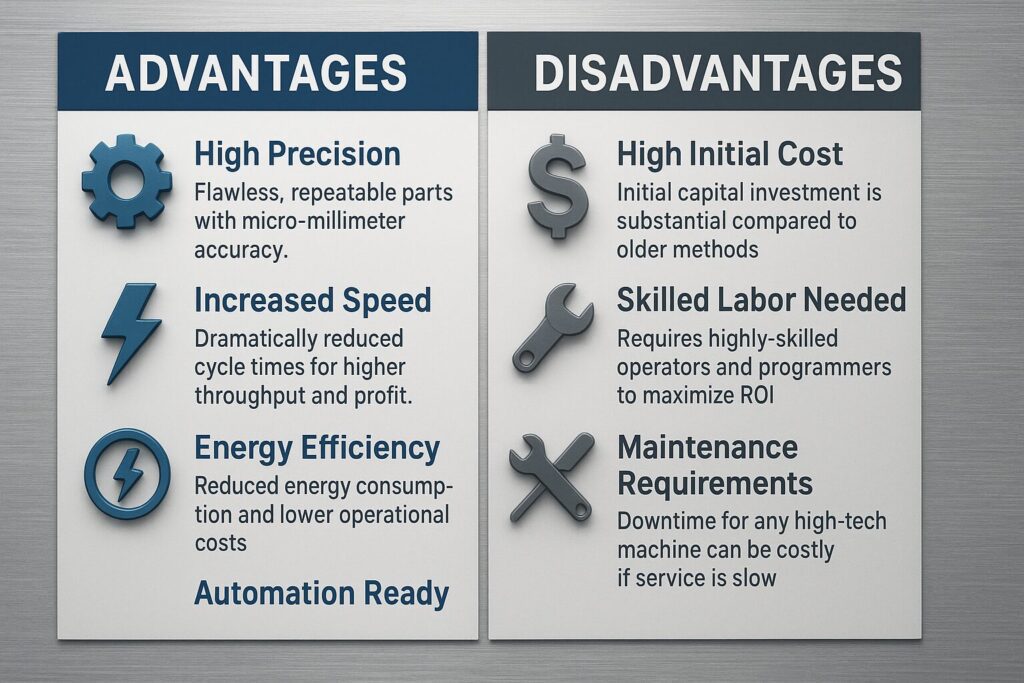

| Category | Advantage (Pro) | Disadvantage (Con) |

| Precision | Flawless, repeatable parts with micro-millimeter accuracy. | Initial capital investment is substantial compared to older methods. |

| Speed/Efficiency | Dramatically reduced cycle times for higher throughput and profit. | Requires highly-skilled operators and programmers to maximize ROI. |

| Future-Proofing | Integration of robotics and AI for next-generation automation. | Downtime for any high-tech machine can be costly if service is slow. |

We at Etana Corp understand this investment is significant. We counter the “disadvantage” of slow service by offering comprehensive local support across the nation. For a deeper dive into which machine suits your budget and goals, read our detailed blog

To ensure your high-ticket fabrication machine, whether a press brake in New York or a CNC cutter in California, lasts 15-20 years or more, consistent maintenance is non-negotiable.

Daily Cleanliness: Remove metal chips, slag, and dust from the work area, especially around precision components like linear guides and optics.

Calibration Checks: Periodically verify the machine’s zero points and tool alignment. This is crucial for maintaining the promised level of precision.

Fluid Management: Regularly inspect and top off or replace hydraulic fluids, lubrication oils, and cooling system water/antifreeze mixtures.

Tooling Inspection: Check press brake tooling (dies, punches) and laser nozzles for wear or damage, replacing them before they impact part quality.

Software Updates: Keep the machine’s CNC operating system and integrated software updated for optimal performance and security.

Note: While some suppliers, like us at Etana Corp, do not provide operator training and machine installation services directly, we do partner you with certified local integrators and service providers in your state who specialize in these initial setup services, ensuring your team is ready to go from day one. You can trust that our machines, from a fiber laser to a busbar machine, are top quality.

Etana Corp is dedicated to being one of the best fabrication and CNC machine suppliers in the United States. We offer high-performance, proven machinery tailored for the American market. If you are specifically looking at expanding your forming capabilities in the South, you might want to look at our specialist machinery in our blog post on Fabrication Machines in Texas.

We provide the reliable equipment you need high performance Press Brakes, advanced Laser Cutters, and efficient Punching Machines to secure the highest-value contracts. Before making your final decision, check out our resource on Fabrication Machine In The United States.

Don’t settle for less than the best. Request a Quote or Schedule a Consultation with an Etana Corp specialist today to discuss the perfect high-ticket machinery solution for your operation.

In the competitive landscape of the U.S. manufacturing sector, the quality and capability of your fabrication machinery are non-negotiable. By investing in the latest CNC technology from a dedicated partner like Etana Corp, you are not just buying a machine; you are securing your future profitability and ability to compete on the global stage. We proudly stand as one of the best fabrication and CNC machine suppliers in the United States, ready to partner with manufacturers from the Northeast to the Pacific Coast. Contact us today to begin your journey toward unparalleled precision and efficiency.

The ROI often comes from reduced scrap material, faster cycle times, and the ability to accept higher-value, tighter-tolerance contracts. Most manufacturers see a strong ROI within 3-5 years, depending on utilization and cost.

For most general sheet metal fabrication today, the Fiber Laser is superior. It is significantly faster, more energy efficient, requires less maintenance, and provides excellent cut quality on thin to medium-thick metals. CO2 is primarily reserved for specialized applications.

Start by analyzing your largest current part size and the thickest, longest piece you anticipate bending or cutting, using the strongest material. This dictates the required working envelope and tonnage. Etana Corp consultants can help you calculate the precise specifications you need.

Beyond the quality of the machine itself, the most critical factor is local after-sales support and parts availability. Downtime kills profitability. Choosing a supplier with a strong national presence, like Etana Corp, ensures rapid service to minimize costly shutdowns.

Yes, modern, high-rigidity CNC machines combined with the latest fiber laser technology are specifically engineered to process high-strength steel, aluminum alloys, and titanium with the necessary precision and power required for demanding sectors like aerospace and automotive.

Etana Corp supplies high-performance CNC fabrication machinery. We recommend that all purchasers partner with qualified, local third-party providers for machine installation, setup, and operator training to ensure safe and optimal usage. Your local dealer can assist with these referrals.

Muratec (Murata Machinery, Ltd.) delivers cutting-edge solutions across logistics, automation, machine tools, sheet metal machinery, textile systems, and communication equipment — driving innovation and quality to support industrial transformation.

Laguna Tools goes beyond machinery — we’re your partner in precision, productivity, and creativity. Our CNC routers and equipment deliver durability, accuracy, and craftsmanship to help bring your vision to life and grow your business.

Boschert Gizelis operates two privately owned factories and is dedicated to continuous R&D investment to deliver high-quality, technologically advanced sheet metal processing machines that meet the evolving industry needs.

Contact us

WhatsApp us