Manufactures Where Speed Meets Accuracy in Industrial Cutting

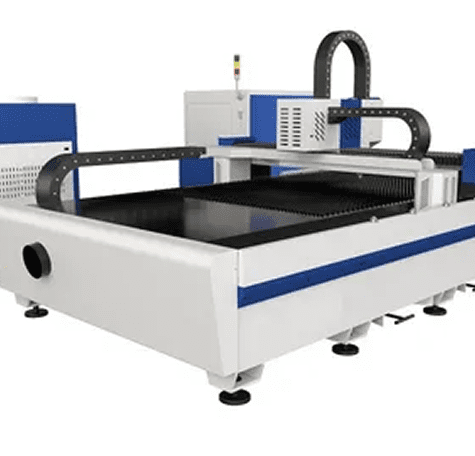

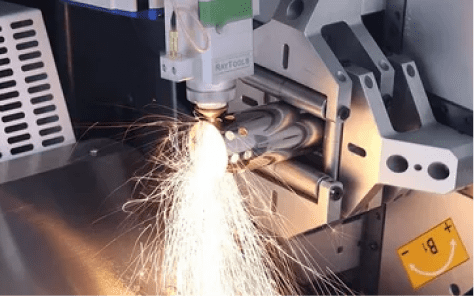

Etana’s suppliers are Laser Cutting Machines that are built for fast, precise, and versatile cutting of metals and composites. Deliver intricate parts with minimal finishing and maximise productivity.

Energy-efficient, high-performance cutting

Ideal for non-metal and hybrid cutting

For high-volume, 24/7 production

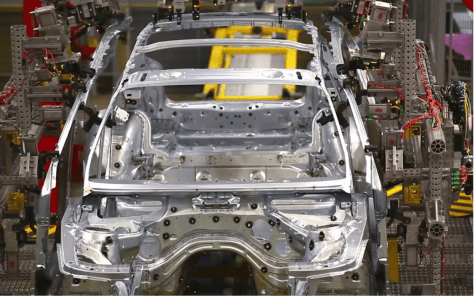

High-speed CNC fiber laser cutting ensures precision and efficiency for the United States automotive panels and parts production.

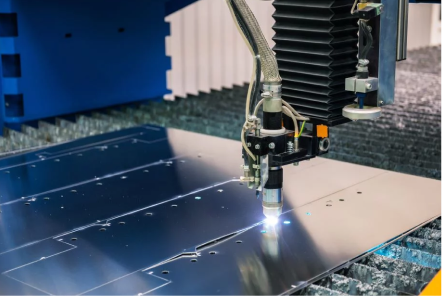

Ultra-accurate laser systems are utilized for reliable, clean-edge aerospace sheet metal cutting of specialized alloys.

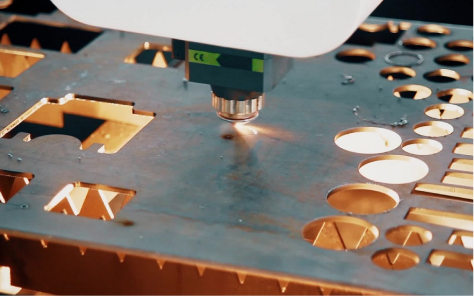

Detailed and decorative laser cutting is performed for custom signage and architectural panels in U.S. construction and design projects.

High wattage CNC laser cutters are essential for durable heavy equipment manufacturing and thick steel plate fabrication.

Etana’s experts provide consultation, installation support, and after-sales service to ensure smooth integration.

Etana is a trusted manufacturer of advanced metal fabrication machines, known for its innovative designs and commitment to quality. Based in Texas, United States, Etana specializes in equipment such as CNC plasma cutters, laser cutting systems, and press brakes, tailored to industries including automotive, aerospace, and construction.

The fiber laser is often chosen for metal cutting because its light is absorbed more fully by metal materials.

Fiber lasers are known to be used with less electricity, which means they are cheaper to run every day.

The maximum thickness that can be cut is decided by the power (or wattage) of the laser machine that is used.

That hard material is called dross. It is made of melted metal that was not pushed completely out of the cut area.

Yes, shiny metals like copper and brass can be cut efficiently because the fiber laser’s beam is taken in very well by those materials.

This question reflects a user’s desire to understand the value proposition of CNC technology. They want to know how these machines can improve efficiency, accuracy, and overall productivity.