Manufacturers Where Precision Bending for Complex Fabrication Needs

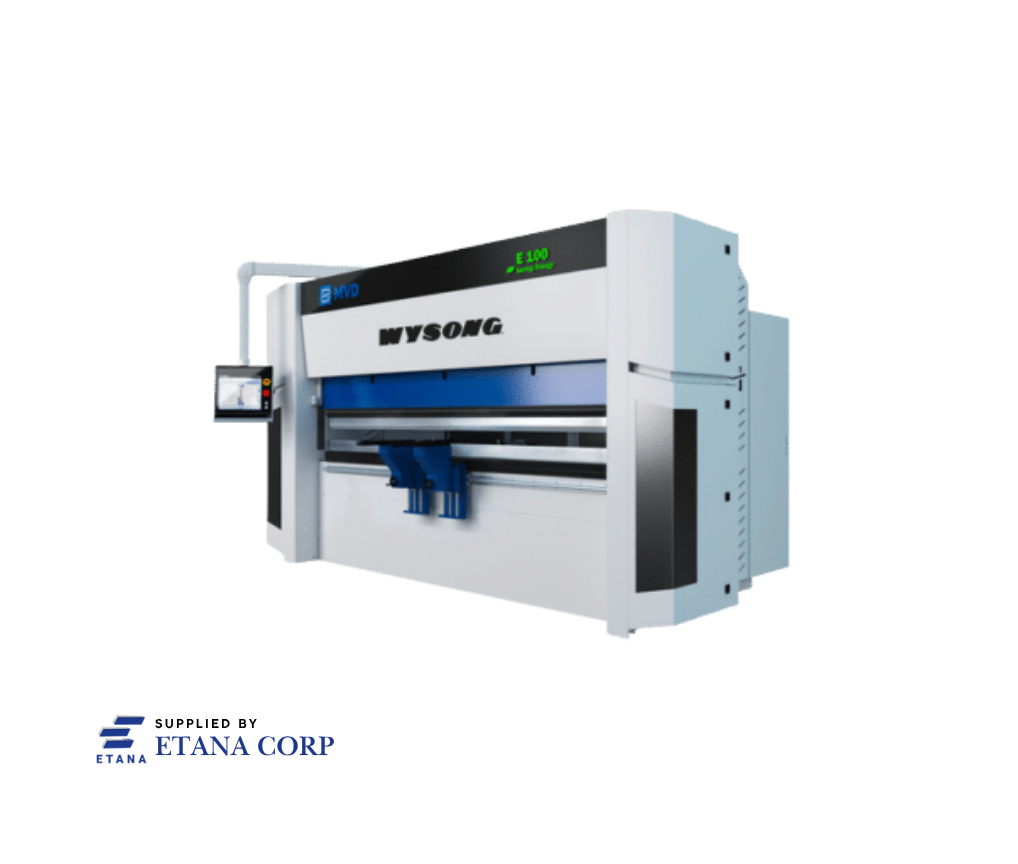

Etana’s Press Brake Tooling is built for accuracy, durability, and easy switching. It includes punches, and custom tools for all bending needs.

Advanced control for intricate bends

Powerful, reliable bending for thick materials

Energy-efficient, precise, and ideal for smaller runs

Structural automotive body and chassis components are fabricated with the highest precision using reliable CNC laser cutting technology.

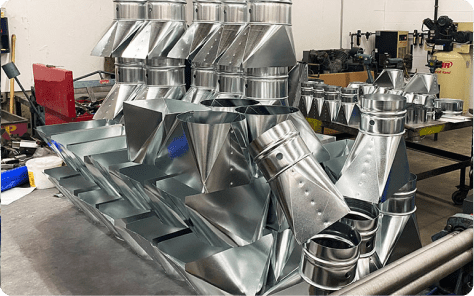

High-volume sheet metal fabrication for efficient HVAC ducts and enclosures is achieved with fast laser cutting machines.

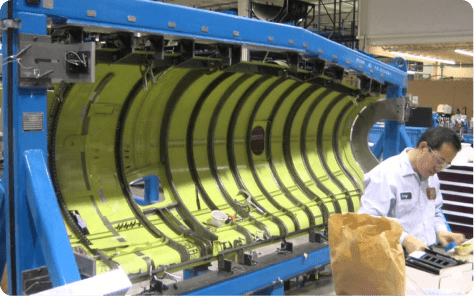

Critical aerospace-grade sheet structures are produced with ultra-high accuracy fiber laser systems for lightweight integrity.

Versatile laser cutting services support general fabrication and construction needs for various metal parts and structures.

Etana’s experts provide consultation, installation support, and after-sales service to ensure smooth integration.

Etana is a trusted manufacturer of advanced metal fabrication machines, known for its innovative designs and commitment to quality. Based in San Francisco, United States, Etana specializes in equipment such as CNC plasma cutters, laser cutting systems, and press brakes, tailored to industries including automotive, aerospace, and construction.

This machine is used to bend flat pieces of metal. Great force is used to press the metal between an upper tool (punch) and a lower tool, giving the metal a sharp, lasting bend so it can be made into useful shapes.

The older hydraulic machines use oil and are very powerful for thick metal. The newer electric ones are known to be much faster, use less energy, and are more accurate when very precise parts need to be made.

This is usually caused by something called springback, where the metal tries to move back to its flat shape after being bent. It is also a problem when the machine’s tools are worn out or are not lined up exactly right.

Operators are kept safe by systems like light curtains and laser scanners. If a hand or object is seen entering the bending area, the machine’s movement is instantly stopped so that nobody is hurt.

The price for a powerful CNC press brake can be very high. They are often sold for anywhere from $50,000 to over $200,000, depending on how big and powerful the machine is and what features are included.

This question reflects a user’s desire to understand the value proposition of CNC technology. They want to know how these machines can improve efficiency, accuracy, and overall productivity.

WhatsApp us