Manufacturers Where Reliable, Repeatable Results Every Time

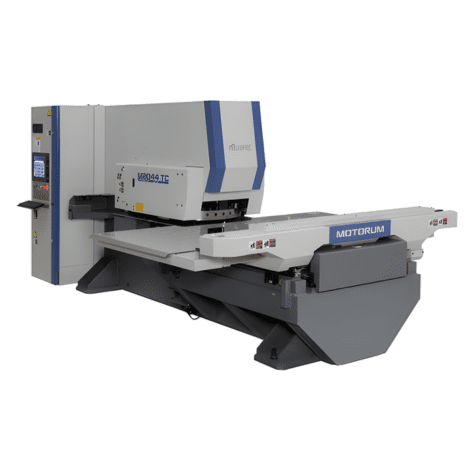

Etana’s Punching Machines are designed for efficient sheet metal and busbar processing. With consistent performance and reduced scrap, they ensure cost-effective production.

Programmable precision punching

Heavy-duty punching for thick materials

High-volume production systems

Accurate sheet metal fabrication of electrical panels and enclosures is ensured by high-precision CNC cutting for reliability.

Cost-effective, high-volume laser cutting is essential for aesthetic and structural metal furniture and office equipment components.

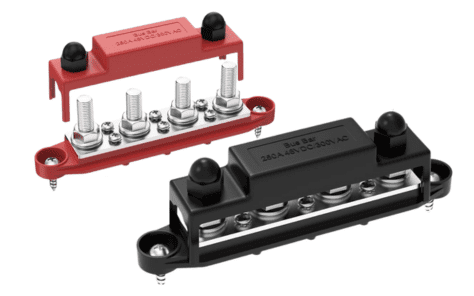

Precise cutting and punching are provided for busbars and power distribution parts, specializing in copper and other highly conductive metals.

Versatile and reliable laser fabrication services produce critical metal components for all phases of general industrial manufacturing.

Etana’s experts provide consultation, installation support, and after-sales service to ensure smooth integration.

Etana is a trusted manufacturer of advanced metal fabrication machines, known for its innovative designs and commitment to quality. Based in Florida, United States, Etana specializes in equipment such as CNC plasma cutters, laser cutting systems, and press brakes, tailored to industries including automotive, aerospace, and construction.

Punching is usually chosen when a very high number of the same parts are needed or when special shapes like bends and louvers are asked for.

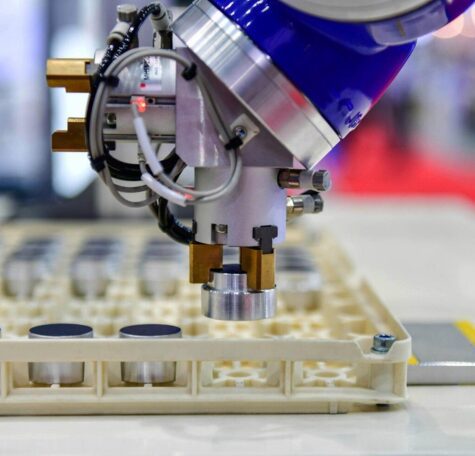

Besides making simple round holes, the punching tools are used to make special forms in the metal, such as a raised part or a little vent.

Most often, sheet metal up to about a quarter-inch thick is cut with a turret punch press for the best results.

The press is controlled by either a mechanical drive, a hydraulic pump, or a clean and fast electric servo motor.

Yes, the running costs for a punch machine are generally known to be much lower, which is why it is used for big jobs.

This question reflects a user’s desire to understand the value proposition of CNC technology. They want to know how these machines can improve efficiency, accuracy, and overall productivity.

WhatsApp us